Choosing The Right Wire Size For A 100 Amp Panel: A Comprehensive Guide

Selecting the correct wire size for a 100 amp panel is crucial for ensuring the safety and functionality of your electrical system. Whether you're upgrading your home's electrical panel or installing a new one, understanding the appropriate wire gauge is essential. Using the wrong size can lead to overheating, electrical fires, or inefficient energy distribution. This guide dives into the nuances of wire sizing, helping you make informed decisions for your electrical needs.

Electrical systems are the backbone of modern homes, powering everything from appliances to lighting. When it comes to a 100 amp panel, which is a common choice for residential setups, the wire size plays a pivotal role. Choosing the right gauge ensures that your system can handle the electrical load without compromising safety. In this article, we’ll explore the factors influencing wire size selection, discuss the types of wires available, and provide practical tips for installation.

With so much at stake, homeowners and electricians alike need a reliable resource to guide them through the process. This article aims to be that resource, offering a detailed breakdown of everything you need to know about wire size for 100 amp panels. From understanding the basics to addressing common questions, we’ve got you covered. Let’s dive in and demystify this critical aspect of electrical systems.

Read also:Discover The Magic Of Richard Dreyfuss Movies A Journey Through Time

Table of Contents

- What Factors Determine the Right Wire Size for 100 Amp Panel?

- Types of Wires Commonly Used for 100 Amp Panels

- How to Calculate the Appropriate Wire Size for Your 100 Amp Panel?

- Why Is Copper Wire Preferred for 100 Amp Panels?

- What Are the Safety Considerations for Wire Size in 100 Amp Panels?

- How to Install Wires for a 100 Amp Panel Correctly?

- What Are the Common Mistakes to Avoid When Selecting Wire Size?

- FAQs About Wire Size for 100 Amp Panel

What Factors Determine the Right Wire Size for 100 Amp Panel?

Choosing the right wire size for a 100 amp panel involves several key factors. Understanding these elements ensures that your electrical system operates safely and efficiently. Let’s explore the primary considerations:

Electrical Load and Ampacity

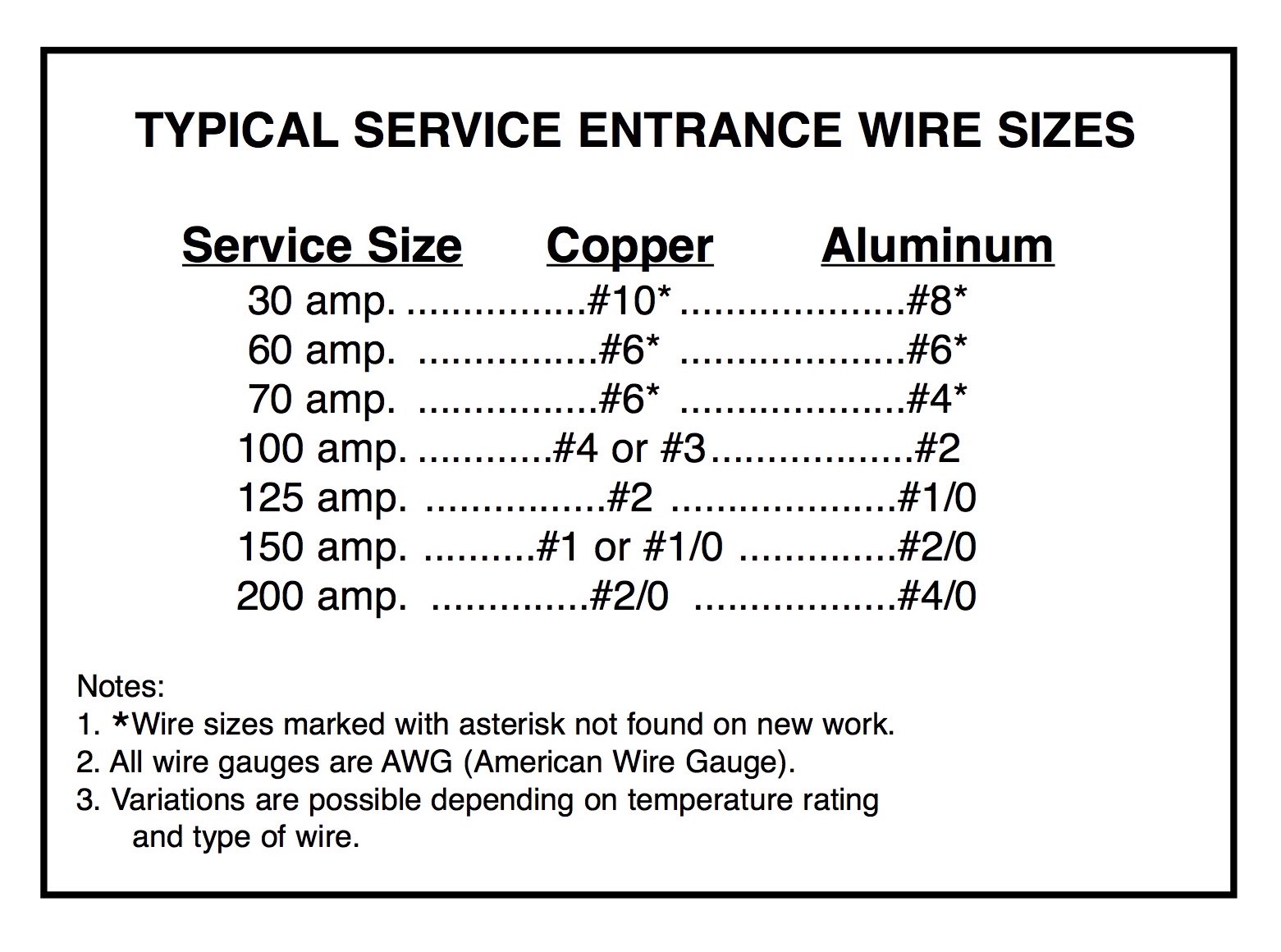

The electrical load, or the amount of current your system needs to handle, is the most critical factor. Ampacity refers to the maximum current a wire can safely carry. For a 100 amp panel, the wire must have an ampacity rating that matches or exceeds this value. Typically, a 2-gauge copper wire or a 1/0-gauge aluminum wire is recommended for a 100 amp panel, as they can handle the load without overheating.

Wire Material: Copper vs. Aluminum

The material of the wire significantly impacts its performance. Copper wires are more conductive and durable, making them ideal for high-load applications. Aluminum wires, while less expensive, are bulkier and require larger gauges to achieve the same ampacity. For a 100 amp panel, copper wires are often preferred due to their superior performance and longevity.

Distance from the Power Source

The distance between the power source and the panel also affects wire size. Longer distances result in voltage drop, which can reduce the efficiency of your electrical system. To counteract this, thicker wires may be required to maintain consistent voltage levels. For instance, if your panel is located far from the main power source, you might need to upgrade to a 1-gauge copper wire or a 2/0-gauge aluminum wire.

Ambient Temperature and Insulation

Environmental conditions, such as ambient temperature, play a role in wire selection. High temperatures can reduce a wire’s ampacity, necessitating a larger gauge. Additionally, the type of insulation used on the wire affects its heat resistance and durability. THHN/THWN insulation is commonly used for its ability to withstand high temperatures and moisture.

Types of Wires Commonly Used for 100 Amp Panels

When it comes to selecting wires for a 100 amp panel, several types are commonly used. Each type has its own advantages and considerations, making it essential to choose the right one for your specific needs.

Read also:Discover Robie Uniacke A Journey Into His Life And Achievements

Copper Wires: The Gold Standard

Copper wires are widely regarded as the best choice for electrical applications due to their high conductivity and durability. They are resistant to corrosion and can handle higher loads without overheating. For a 100 amp panel, 2-gauge copper wires are typically recommended, as they provide excellent performance and safety.

Aluminum Wires: A Cost-Effective Alternative

Aluminum wires are a more affordable option but come with some trade-offs. They are less conductive than copper, requiring larger gauges to achieve the same ampacity. For a 100 amp panel, 1/0-gauge aluminum wires are often used. While they are suitable for many applications, they may not be ideal for long-distance runs or high-temperature environments.

Stranded vs. Solid Wires

Wires can be either stranded or solid, each with its own benefits. Stranded wires are more flexible and easier to work with, especially in tight spaces. Solid wires, on the other hand, are more durable and better suited for permanent installations. For a 100 amp panel, stranded wires are often preferred due to their flexibility and ease of installation.

Insulation Types and Their Importance

The type of insulation used on the wire is another critical factor. Common insulation types include THHN, THWN, and XHHW. These insulations are designed to withstand high temperatures and moisture, ensuring the wire remains safe and functional. For a 100 amp panel, THHN/THWN insulation is often recommended due to its versatility and durability.

How to Calculate the Appropriate Wire Size for Your 100 Amp Panel?

Calculating the correct wire size for a 100 amp panel involves a few straightforward steps. By following these guidelines, you can ensure your electrical system is both safe and efficient.

Step 1: Determine the Electrical Load

The first step is to calculate the total electrical load your panel will need to handle. This includes all appliances, lighting, and other electrical devices connected to the system. For a 100 amp panel, the wire must be able to handle this load without exceeding its ampacity rating.

Step 2: Consult the National Electrical Code (NEC)

The NEC provides guidelines for wire sizing based on ampacity and other factors. According to the NEC, a 2-gauge copper wire or a 1/0-gauge aluminum wire is typically recommended for a 100 amp panel. These guidelines ensure that the wire can safely carry the required current without overheating.

Step 3: Account for Voltage Drop

Voltage drop occurs when the distance between the power source and the panel is significant. To minimize voltage drop, you may need to use a larger gauge wire. For example, if your panel is located far from the main power source, upgrading to a 1-gauge copper wire or a 2/0-gauge aluminum wire may be necessary.

Step 4: Consider Environmental Factors

Environmental conditions, such as ambient temperature and moisture levels, can affect wire performance. High temperatures reduce a wire’s ampacity, while moisture can lead to corrosion. Choosing the right insulation type, such as THHN/THWN, helps mitigate these issues and ensures long-term reliability.

Why Is Copper Wire Preferred for 100 Amp Panels?

Copper wires are the preferred choice for 100 amp panels due to their superior conductivity, durability, and resistance to corrosion. Let’s explore why copper stands out as the best option for this application.

Superior Conductivity

Copper is one of the most conductive materials available, making it ideal for high-load electrical systems. Its ability to efficiently carry current reduces the risk of overheating and ensures consistent performance. For a 100 amp panel, this translates to safer and more reliable operation.

Longevity and Durability

Copper wires are highly durable and resistant to wear and tear. They can withstand high temperatures and are less prone to damage from environmental factors. This longevity makes them a cost-effective choice in the long run, as they require less maintenance and replacement compared to other materials.

Resistance to Corrosion

Corrosion can compromise the performance and safety of electrical wires. Copper’s natural resistance to corrosion ensures that it remains functional and safe over time. This is particularly important for outdoor or damp environments, where moisture can accelerate corrosion in other materials like aluminum.

Flexibility and Ease of Installation

Copper wires are more flexible than aluminum, making them easier to work with during installation. This flexibility is especially beneficial in tight spaces or complex wiring setups. For a 100 amp panel, this ease of installation can save time and reduce labor costs.

What Are the Safety Considerations for Wire Size in 100 Amp Panels?

Safety is paramount when selecting the wire size for a 100 amp panel. Proper wire sizing ensures that your electrical system operates safely and efficiently, minimizing the risk of hazards such as overheating and electrical fires.

Preventing Overheating

Using a wire that is too small for the electrical load can lead to overheating. Overheating not only damages the wire but also poses a significant fire risk. For a 100 amp panel, selecting a wire with the appropriate ampacity, such as a 2-gauge copper wire, ensures that the system can handle the load without overheating.

Reducing Voltage Drop

Voltage drop can reduce the efficiency of your electrical system and cause appliances to underperform. To minimize voltage drop, it’s essential to use the correct wire size, especially for long-distance runs. For a 100 amp panel, upgrading to a larger gauge wire, such as a 1-gauge copper wire, may be necessary to maintain consistent voltage levels.

Ensuring Proper Insulation

The type of insulation used on the wire is critical for safety. Insulation protects the wire from environmental factors such as moisture and high temperatures. For a 100 amp panel, using wires with THHN/THWN insulation ensures that they remain safe and functional under various conditions.

Compliance with Electrical Codes

Adhering to electrical codes, such as those outlined in the NEC, is essential for safety. These codes provide guidelines for wire sizing and installation, ensuring that your electrical system meets industry standards. For a 100 amp panel, following these guidelines helps prevent hazards and ensures compliance with local regulations.

How to Install Wires for a 100 Amp Panel Correctly?

Proper installation of wires for a 100 amp panel is crucial for ensuring the safety and efficiency of your electrical system. Follow these steps to ensure a correct and safe installation.

Step 1: Turn Off the Power

Before beginning any electrical work, always turn off the power at the main breaker. This ensures your safety and prevents accidental electrocution. Use a voltage tester to confirm that the power is off before proceeding.

Step 2: Plan the Wiring Route

Plan the route for the wires, ensuring they are protected from damage and environmental factors. Use conduit or cable trays to shield the wires, especially in areas

Understanding The Differences: Lake Vs. Pond – A Comprehensive Guide

Top Haircut Designs For Men: Styles, Trends, And Inspiration

Exploring Timothy Treadwell's Net Worth And Legacy: A Comprehensive Guide

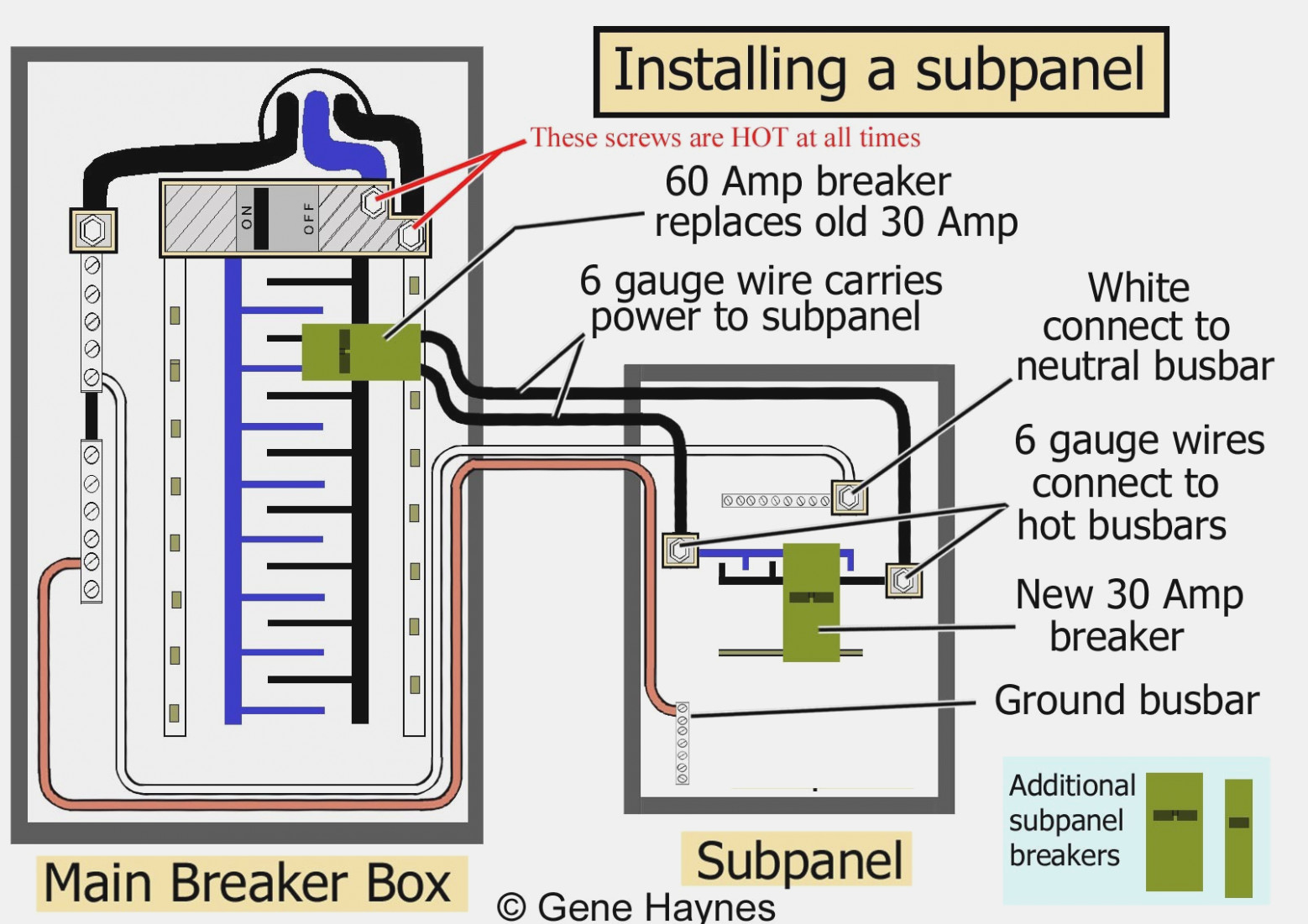

What Size Ground Wire For 100 Amp Sub Panel

100 Amp Sub Panel Wire Diagram