What Gauge Is 100 Amp Wire? A Comprehensive Guide For Electrical Projects

Choosing the right wire gauge for your electrical system is crucial for safety, efficiency, and compliance with electrical codes. When it comes to handling a 100-amp service, knowing the appropriate wire gauge is essential to avoid overheating, voltage drops, and potential hazards. A 100-amp service is a common setup for residential homes, small businesses, and workshops, but the wire gauge requirements can vary based on factors like distance, material, and environmental conditions. This guide will walk you through everything you need to know about wire gauges for 100-amp circuits, ensuring you make informed decisions for your electrical projects.

Understanding wire gauge isn't just about picking a number; it involves considering the specific needs of your electrical setup. Copper and aluminum wires, for instance, have different carrying capacities, and the distance between the power source and the load plays a significant role in determining the correct gauge. Additionally, local building codes and regulations often dictate minimum requirements, making it essential to stay informed. Whether you're a DIY enthusiast or a professional electrician, this article will provide you with the expertise to confidently select the right wire gauge for a 100-amp service.

As we delve deeper into the topic, you'll discover the nuances of wire gauge selection, including the impact of material conductivity, insulation types, and the role of voltage drop in long-distance wiring. By the end of this guide, you'll not only know what gauge is 100 amp wire but also understand the reasoning behind it. With safety and efficiency at the forefront, this article is designed to equip you with the knowledge to tackle your electrical projects confidently and responsibly.

Read also:Discover Robie Uniacke A Journey Into His Life And Achievements

Table of Contents

- What is Wire Gauge and Why Does It Matter?

- What Factors Affect the Choice of Wire Gauge for 100 Amp Service?

- Copper vs. Aluminum Wires: Which is Best for 100 Amp Circuits?

- How Does Insulation and Environment Affect Wire Gauge?

- What Are the Code Requirements for 100 Amp Wire Gauge?

- What Are the Common Mistakes to Avoid When Choosing Wire Gauge?

- Tools and Resources for Selecting the Right Wire Gauge

- Frequently Asked Questions About 100 Amp Wire Gauge

What is Wire Gauge and Why Does It Matter?

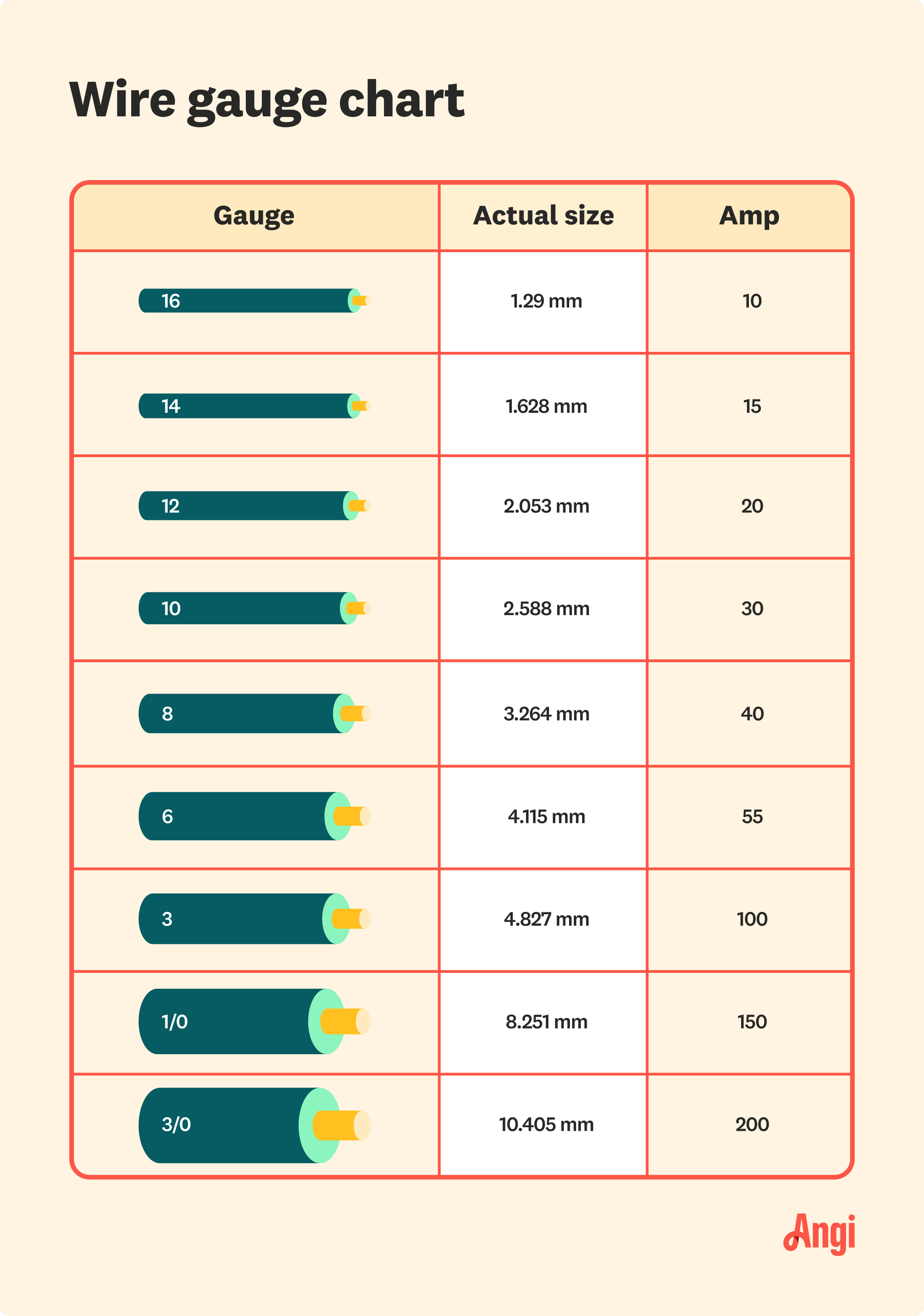

Wire gauge refers to the diameter of the conductor within an electrical wire, typically measured using the American Wire Gauge (AWG) system. The AWG scale is inversely proportional, meaning that as the gauge number decreases, the wire's diameter increases. For example, a 1 AWG wire is significantly thicker than a 10 AWG wire. This measurement is critical because it directly impacts the wire's ability to carry electrical current without overheating or causing voltage drops.

When working with a 100-amp service, selecting the correct wire gauge is vital for ensuring safety and performance. A wire that's too thin for the current load can overheat, leading to insulation damage, fires, or even complete circuit failure. On the other hand, using a wire that's unnecessarily thick can increase costs and make installation cumbersome. For most residential 100-amp services, the recommended wire gauge is typically 2 AWG for copper wires or 1/0 AWG for aluminum wires, though these recommendations can vary based on specific conditions.

Understanding wire gauge also helps in optimizing energy efficiency. A properly sized wire minimizes energy loss due to resistance, ensuring that your electrical system operates at peak performance. This is particularly important for long-distance wiring, where voltage drop can become a significant issue. By grasping the basics of wire gauge, you'll be better equipped to make informed decisions that balance safety, cost, and functionality.

What Factors Affect the Choice of Wire Gauge for 100 Amp Service?

Several factors come into play when determining the appropriate wire gauge for a 100-amp service. These include the type of material used for the wire, the distance between the power source and the load, and environmental conditions such as temperature and exposure to moisture. Each of these factors influences the wire's ability to safely and efficiently carry the required current.

How Does Material Conductivity Influence Wire Gauge?

The material of the wire—typically copper or aluminum—plays a significant role in determining the required gauge. Copper is a superior conductor compared to aluminum, meaning it can carry more current at a smaller diameter. For a 100-amp service, copper wires generally require a 2 AWG gauge, while aluminum wires need a larger 1/0 AWG gauge to handle the same load. This difference is due to aluminum's lower conductivity, which necessitates a thicker wire to compensate.

While copper wires are more expensive upfront, they offer better performance and longevity, making them a popular choice for residential and commercial applications. Aluminum, on the other hand, is lighter and more cost-effective, making it suitable for larger-scale installations where weight and budget are concerns. However, aluminum wires require careful installation to prevent issues like oxidation and loosening at connection points, which can lead to overheating.

Read also:Discover The Magic Of Richard Dreyfuss Movies A Journey Through Time

Why Does Distance and Voltage Drop Matter in Wire Selection?

The distance between the power source and the load is another critical factor in wire gauge selection. Longer distances increase the resistance of the wire, leading to voltage drop, which can affect the performance of electrical devices. For a 100-amp service, the National Electrical Code (NEC) recommends limiting voltage drop to 3% for branch circuits and 5% for feeders to ensure optimal performance.

To mitigate voltage drop, you may need to use a thicker wire gauge than the standard recommendation. For instance, if the distance between the main panel and the subpanel exceeds 100 feet, upgrading from a 2 AWG copper wire to a 1 AWG copper wire might be necessary. Calculating voltage drop involves considering the wire's resistance, the current load, and the length of the run. Tools like voltage drop calculators can simplify this process, ensuring you select the appropriate gauge for your specific setup.

Copper vs. Aluminum Wires: Which is Best for 100 Amp Circuits?

Choosing between copper and aluminum wires for a 100-amp service involves weighing the pros and cons of each material. Copper wires are renowned for their superior conductivity, durability, and resistance to corrosion. These qualities make them ideal for applications where performance and reliability are paramount. However, copper's higher cost can be a deterrent for budget-conscious projects.

Aluminum wires, while less conductive, offer a cost-effective alternative for large-scale installations. They are lighter and easier to handle, making them suitable for long-distance runs or applications where weight is a concern. However, aluminum wires require special attention during installation to prevent issues like creep (the tendency of the wire to deform over time) and oxidation at connection points. Using anti-oxidant compounds and ensuring proper torque on connectors can help mitigate these risks.

Ultimately, the choice between copper and aluminum depends on your specific needs and constraints. For most residential 100-amp services, copper is the preferred option due to its reliability and ease of installation. However, aluminum can be a viable choice for larger projects where cost and weight are significant considerations.

How Does Insulation and Environment Affect Wire Gauge?

The insulation type and environmental conditions also play a crucial role in wire gauge selection. Different insulation materials have varying temperature ratings, which affect the wire's ability to dissipate heat. For example, THHN (Thermoplastic High Heat-resistant Nylon-coated) wires are commonly used in residential and commercial applications due to their high heat resistance and durability.

Environmental factors such as exposure to sunlight, moisture, and chemicals can degrade insulation over time, impacting the wire's performance. In wet or damp locations, wires with moisture-resistant insulation, such as THWN (Thermoplastic Heat and Water-resistant Nylon-coated), are recommended. Additionally, wires installed in high-temperature environments may require a larger gauge to compensate for reduced current-carrying capacity.

What Are the Code Requirements for 100 Amp Wire Gauge?

Adhering to local building codes and the National Electrical Code (NEC) is essential when selecting wire gauge for a 100-amp service. These codes provide guidelines on minimum wire sizes, insulation types, and installation practices to ensure safety and compliance. For example, the NEC specifies that copper wires for 100-amp services should be at least 2 AWG, while aluminum wires should be 1/0 AWG.

Code compliance also extends to factors like grounding, overcurrent protection, and conduit fill. Failing to meet these requirements can result in fines, project delays, or even safety hazards. Consulting with a licensed electrician or local building authority can help ensure that your wiring meets all applicable standards.

What Are the Common Mistakes to Avoid When Choosing Wire Gauge?

One of the most common mistakes is underestimating the importance of wire gauge, leading to the use of undersized wires that can overheat or cause voltage drops. Other errors include neglecting environmental factors, failing to account for voltage drop in long runs, and using improper connectors for aluminum wires.

Tools and Resources for Selecting the Right Wire Gauge

Several tools and resources can assist in selecting the correct wire gauge for a 100-amp service. Voltage drop calculators, wire size charts, and NEC guidelines are invaluable for making informed decisions. Additionally, consulting with a professional electrician can provide personalized advice tailored to your specific project.

Frequently Asked Questions About 100 Amp Wire Gauge

What gauge is 100 amp wire for copper and aluminum?

For copper wires, the recommended gauge is 2 AWG, while aluminum wires require a 1/0 AWG gauge to handle a 100-amp load safely.

Can I use a smaller gauge wire for short distances?

While it's technically possible to use a smaller gauge for short runs, it's not advisable as it may not meet code requirements and could pose safety risks.

How do I calculate voltage drop for my wiring project?

Voltage drop can be calculated using the formula: Voltage Drop = (2 × Length × Current × Resistance) / 1000. Online calculators are also available for convenience.

In conclusion, understanding what gauge is 100 amp wire is essential for any electrical project involving a 100-amp service. By considering factors like material, distance, insulation, and code compliance, you can ensure a safe and efficient installation. Whether you're a DIY enthusiast or a professional electrician, this guide provides the knowledge and tools to make informed decisions.

For further reading, check out this external link to the National Electrical Code for more detailed guidelines on electrical installations.

Did P Diddy Die: Unraveling The Truth Behind The Rumors

Rafe Cameron Haircut: The Ultimate Guide To Style And Inspiration

How Tall Is Wynonna Judd? A Comprehensive Guide To Her Height, Career, And Legacy

What Is the Correct Wire Size for 100Amp Service? Angi

Speaker wire gauge calculator vetkiza