What Size Wire Is Needed For 100 Amp Service? A Complete Guide

The wire you select must be capable of handling the electrical load safely and efficiently while complying with local building codes. Whether you're upgrading your home's electrical panel or installing a subpanel in a workshop, understanding the requirements for wire gauge, material, and insulation is essential. Failure to use the correct wire can lead to overheating, electrical fires, or system failures, making this a non-negotiable aspect of electrical work. When discussing the wire needed for 100 amp service, it’s important to consider factors like the distance between the main panel and the subpanel, the type of wire material (copper or aluminum), and the environment in which the wire will be installed. For instance, copper wire is more conductive and requires a smaller gauge compared to aluminum, which is less expensive but needs a larger diameter to carry the same current. Additionally, the insulation type must be appropriate for the conditions, such as exposure to moisture, heat, or direct sunlight. These considerations ensure that your electrical system operates safely and efficiently, minimizing risks and maximizing performance. This guide will walk you through everything you need to know about the wire needed for 100 amp service, from understanding the basics of electrical load to selecting the right materials and complying with code requirements. Whether you're a homeowner planning a DIY project or a professional electrician, this article will equip you with the knowledge to make informed decisions. By the end, you'll have a clear understanding of how to choose the correct wire size, the importance of proper installation, and tips for maintaining a safe and reliable electrical system.

Table of Contents

- What is the Wire Needed for 100 Amp Service?

- How Do You Calculate the Wire Size for 100 Amp Service?

- What Are the Types of Wire Materials for 100 Amp Service?

- What Are the Code Requirements for Wire Installation?

- How Does Distance Affect Wire Size Selection?

- What Are the Common Mistakes to Avoid?

- How to Ensure Safety During Installation?

- FAQs About Wire Needed for 100 Amp Service

What is the Wire Needed for 100 Amp Service?

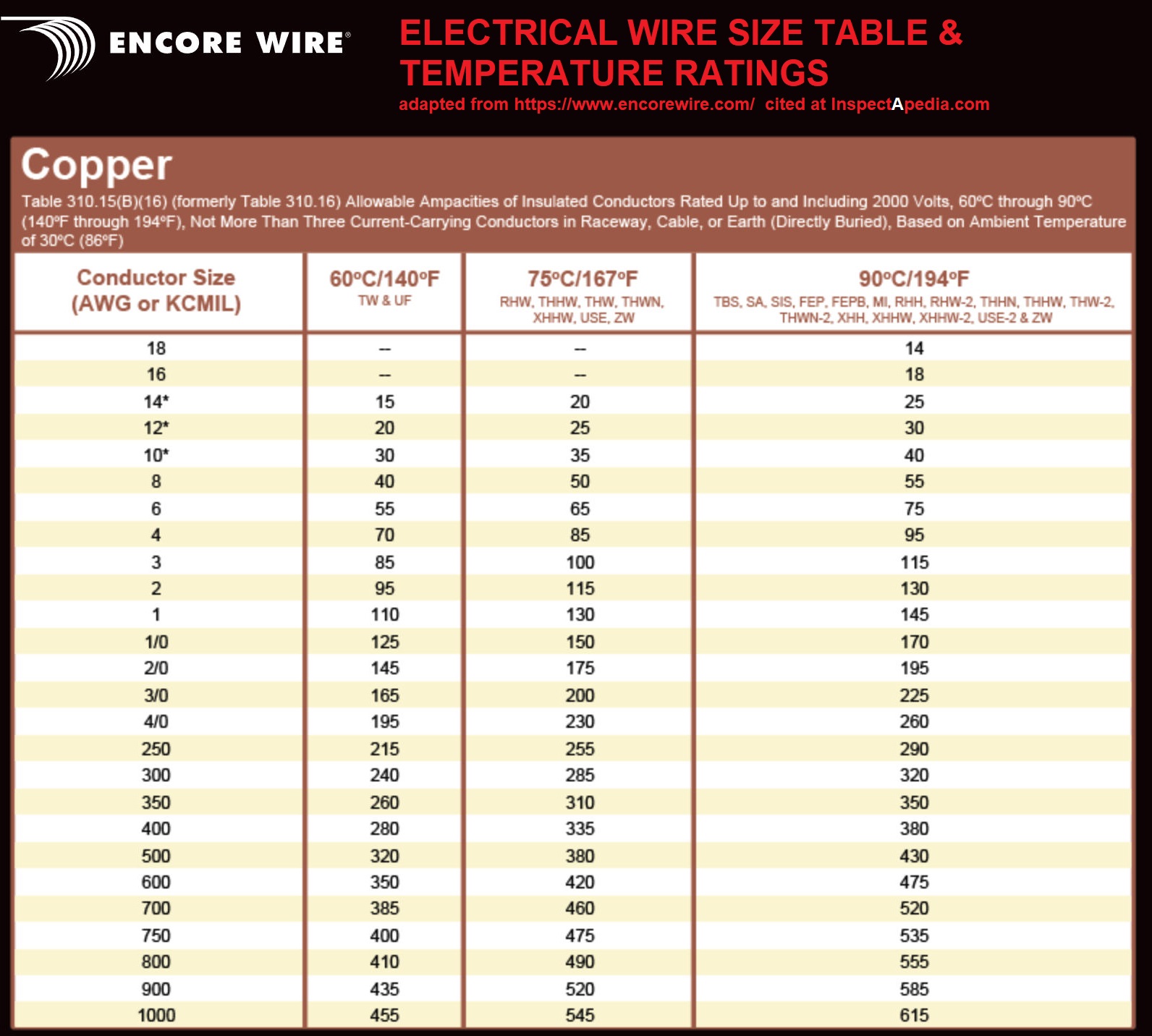

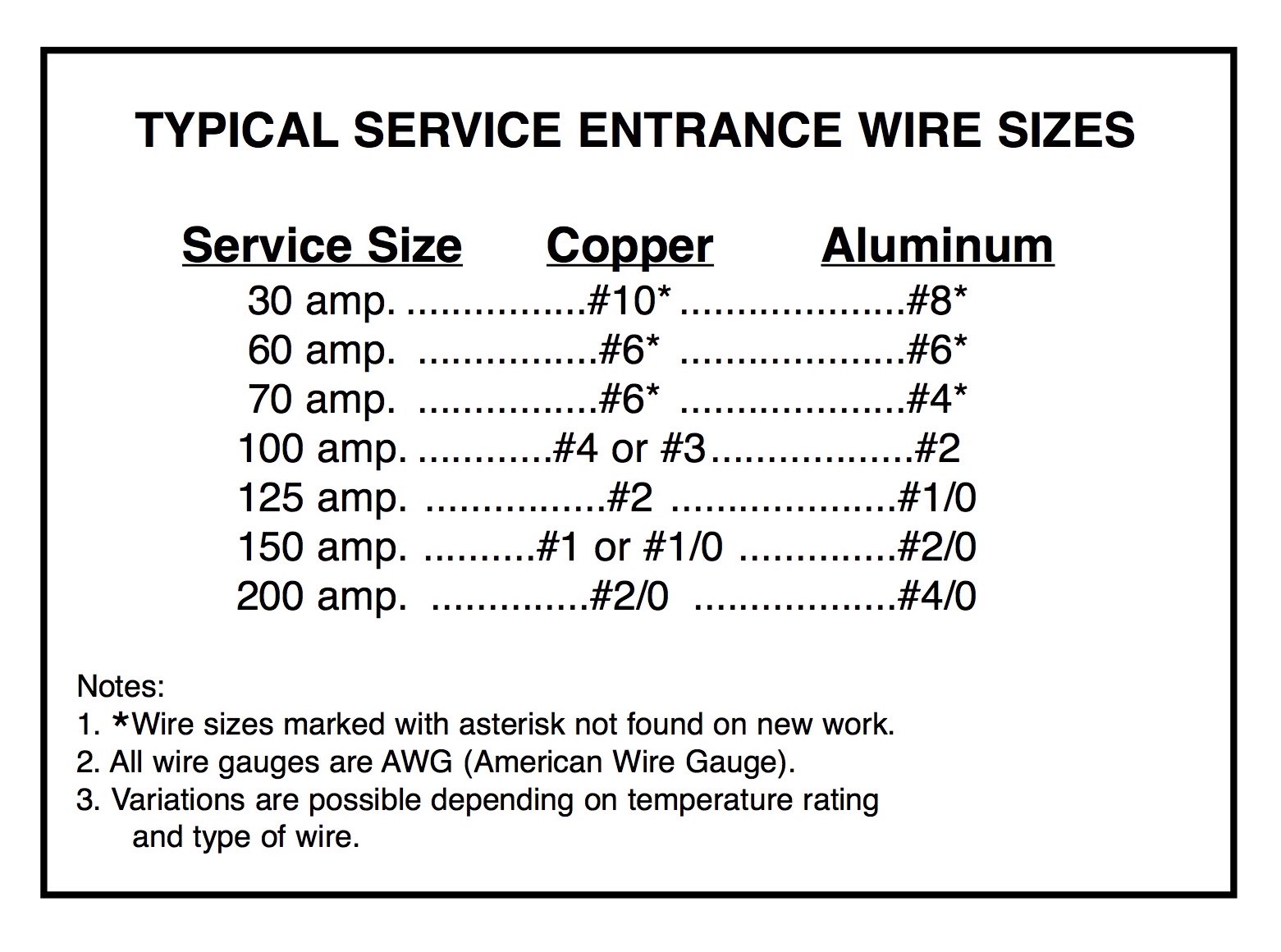

When it comes to the wire needed for 100 amp service, understanding the basics is crucial. A 100 amp service is a common electrical setup for residential homes, providing enough power to handle modern appliances, lighting, and electronics. The wire gauge, or thickness, is determined by the amount of current it needs to carry. For a 100 amp service, the National Electrical Code (NEC) typically recommends using a 3 AWG copper wire or 1/0 AWG aluminum wire. These sizes ensure the wire can handle the load without overheating.

The wire needed for 100 amp service must also meet specific insulation requirements. For example, wires installed in wet or damp locations, such as underground or outdoors, require moisture-resistant insulation like THWN or XHHW. Indoor installations, on the other hand, may use wires with less stringent insulation, such as THHN. It's essential to match the wire's insulation to the environment to prevent damage and ensure long-term performance.

Read also:Discover Robie Uniacke A Journey Into His Life And Achievements

Beyond size and insulation, the wire needed for 100 amp service must be compatible with the breaker and panel. This includes ensuring the wire is rated for the correct voltage and that the connections are secure. Loose or improper connections can lead to resistance, which generates heat and increases the risk of fire. By selecting the appropriate wire and ensuring proper installation, you can create a safe and reliable electrical system.

How Do You Calculate the Wire Size for 100 Amp Service?

Calculating the wire size for 100 amp service involves several key factors, including the electrical load, distance, and material type. The first step is determining the maximum current the wire will carry. For a 100 amp service, the wire must be able to handle 100 amps continuously without exceeding its rated capacity. This is where the American Wire Gauge (AWG) system comes into play, as it provides a standardized way to measure wire thickness.

Distance is another critical factor in wire size calculations. The longer the wire run, the more resistance it encounters, which can lead to voltage drop. A voltage drop of more than 3% is generally considered unacceptable, as it can affect the performance of electrical devices. To minimize voltage drop, you may need to increase the wire gauge. For example, a 100-foot run might require a larger wire than a 50-foot run to maintain efficiency.

Here’s a simple breakdown of the calculation process:

- Determine the total amperage of the circuit (100 amps).

- Measure the distance from the main panel to the subpanel.

- Choose the wire material (copper or aluminum).

- Use a voltage drop calculator or formula to determine the appropriate wire gauge.

By following these steps, you can ensure the wire size is adequate for your 100 amp service, balancing safety, efficiency, and cost.

What Are the Types of Wire Materials for 100 Amp Service?

The wire needed for 100 amp service can be made from different materials, each with its own advantages and disadvantages. The two most common materials are copper and aluminum, and the choice between them often depends on budget, application, and personal preference.

Read also:Unlock The Fun Infinite Craft Unblocked Ndash The Ultimate Guide

Copper vs. Aluminum Wire

Copper is the preferred material for many electricians due to its superior conductivity. It requires a smaller gauge to carry the same current as aluminum, making it more compact and easier to work with. For example, a 3 AWG copper wire can handle 100 amps, while a 1/0 AWG aluminum wire is needed for the same load. Copper is also more resistant to corrosion, which extends its lifespan and reduces maintenance needs.

Aluminum, on the other hand, is lighter and more affordable than copper. This makes it a popular choice for long-distance runs or large-scale projects where cost is a significant factor. However, aluminum is less conductive, requiring a larger gauge to compensate. It’s also more prone to oxidation, which can cause connections to loosen over time. To mitigate this, electricians often use anti-oxidant compounds and specialized connectors designed for aluminum wiring.

Insulation Types and Their Importance

The insulation on the wire needed for 100 amp service plays a vital role in its performance and safety. Common insulation types include:

- THHN/THWN: Suitable for dry and wet locations, making it versatile for indoor and outdoor use.

- XHHW: Designed for high-heat environments and often used in commercial or industrial settings.

- UF-B: Used for underground installations, providing additional protection against moisture and physical damage.

Choosing the right insulation ensures the wire can withstand environmental conditions and perform reliably over time.

What Are the Code Requirements for Wire Installation?

Installing the wire needed for 100 amp service must comply with the National Electrical Code (NEC) and local building codes. These regulations are designed to ensure safety and prevent electrical hazards. One key requirement is the use of appropriately sized wires, as undersized wires can overheat and cause fires. The NEC provides specific guidelines for wire gauge based on the amperage and type of installation.

Another important code requirement is the use of conduit for certain types of wiring. For example, wires installed in exposed areas or underground must be protected by conduit to prevent damage. Additionally, the NEC mandates the use of grounding wires to ensure electrical safety. Grounding provides a path for excess electricity to dissipate, reducing the risk of shock or fire.

It’s also essential to follow code requirements for wire connections. Loose or improper connections can lead to arcing, which generates heat and increases the risk of fire. Using the correct connectors and ensuring tight connections are critical steps in the installation process. By adhering to these code requirements, you can ensure a safe and compliant electrical system.

How Does Distance Affect Wire Size Selection?

Distance is a crucial factor when selecting the wire needed for 100 amp service. The longer the wire run, the greater the resistance, which can lead to voltage drop. Voltage drop occurs when the electrical current encounters resistance in the wire, causing a reduction in voltage at the end of the line. This can affect the performance of appliances and devices, leading to inefficiency or malfunction.

To minimize voltage drop, electricians often increase the wire gauge for longer runs. For example, a 50-foot run might require a 3 AWG copper wire, while a 150-foot run might need a 1 AWG copper wire to maintain the same performance. Using a voltage drop calculator can help determine the appropriate wire size based on distance and load.

Here are some tips for managing distance-related challenges:

- Plan the wire route to minimize the total length.

- Use higher-quality wires with better conductivity.

- Consider upgrading to a larger wire gauge if the run exceeds 100 feet.

By accounting for distance, you can ensure your 100 amp service operates efficiently and safely.

What Are the Common Mistakes to Avoid?

When working with the wire needed for 100 amp service, several common mistakes can compromise safety and performance. One frequent error is using undersized wires, which can overheat and cause fires. It’s essential to follow the NEC guidelines and use the correct wire gauge for the load and distance.

Another mistake is neglecting proper insulation. Using wires with inadequate insulation for the environment can lead to damage and electrical failures. For example, using indoor-rated wire outdoors can cause moisture ingress, leading to corrosion and short circuits. Always match the wire’s insulation to the installation conditions.

Improper connections are another common issue. Loose or corroded connections can cause arcing, which generates heat and increases the risk of fire. To avoid this, use the correct connectors and ensure all connections are tight and secure. By avoiding these mistakes, you can create a safe and reliable electrical system.

How to Ensure Safety During Installation?

Safety is paramount when installing the wire needed for 100 amp service. The first step is to turn off the power at the main breaker to prevent electrical shock. Always use insulated tools and wear protective gear, such as gloves and safety glasses, to minimize risks.

Proper planning is also essential for safety. Before starting the installation, create a detailed plan that includes the wire route, connections, and any necessary permits. Following a plan ensures the installation is organized and reduces the likelihood of errors. Additionally, always double-check your work to ensure all connections are secure and the wire is properly installed.

Finally, consider hiring a licensed electrician if you’re unsure about any aspect of the installation. Professional electricians have the expertise and experience to handle complex electrical work safely and efficiently. By prioritizing safety, you can ensure a successful installation and a reliable electrical system.

FAQs About Wire Needed for 100 Amp Service

What size wire is needed for 100 amp service?

For a 100 amp service, the recommended wire size is 3 AWG copper or 1/0 AWG aluminum.

Exploring Layzie Bone Net Worth: Career, Achievements, And More

Discover Your Cosmic Blueprint: January 4th Zodiac Insights

How Do Male Peacock’s Feathers Increase His Fitness? A Fascinating Dive Into Nature’s Design

Wire Needed For 60 Amp 240v

What Size Wire Is Needed For 60 Amp Service