What Wire Size For 100 Amp Service? A Comprehensive Guide To Electrical Wiring

Choosing the correct wire size for a 100 amp service is not just a technical requirement; it's a crucial safety measure that ensures the smooth functioning of your electrical system. Whether you're a homeowner planning an upgrade or a DIY enthusiast tackling a new project, understanding the nuances of wire sizing can prevent costly mistakes and potential hazards. A 100 amp service is standard for many homes, but the wire size you need depends on several factors, including the length of the run, material type, and environmental conditions. This guide will walk you through everything you need to know to make an informed decision.

When it comes to electrical systems, precision is key. Using an undersized wire can lead to overheating, voltage drops, and even fire hazards. On the flip side, opting for a wire that's too large may unnecessarily increase costs without adding significant benefits. The National Electrical Code (NEC) provides guidelines to ensure safety and compliance, but navigating these regulations can be challenging for the uninitiated. This article aims to simplify the process by breaking down the technical jargon into easy-to-understand language while addressing common questions and concerns.

As we delve deeper into the topic, you'll learn about the specific wire gauges recommended for a 100 amp service, the differences between copper and aluminum wires, and the importance of considering voltage drop. We'll also explore how external factors like temperature and conduit type can influence your choice. By the end of this guide, you'll have a clear understanding of what wire size for 100 amp service is best suited for your needs and how to ensure your electrical system is both safe and efficient.

Read also:Discover The Magic Of Richard Dreyfuss Movies A Journey Through Time

Table of Contents

- What Wire Size for 100 Amp Service?

- Why Does Wire Size Matter for Electrical Safety?

- Copper vs. Aluminum: Which Material Is Right for You?

- How to Calculate Voltage Drop for Your Wire?

- What Are the National Electrical Code Requirements?

- How Does Wire Length Affect Your Choice?

- What Are the Best Practices for Installation?

- Frequently Asked Questions About Wire Sizing

What Wire Size for 100 Amp Service? Understanding the Basics

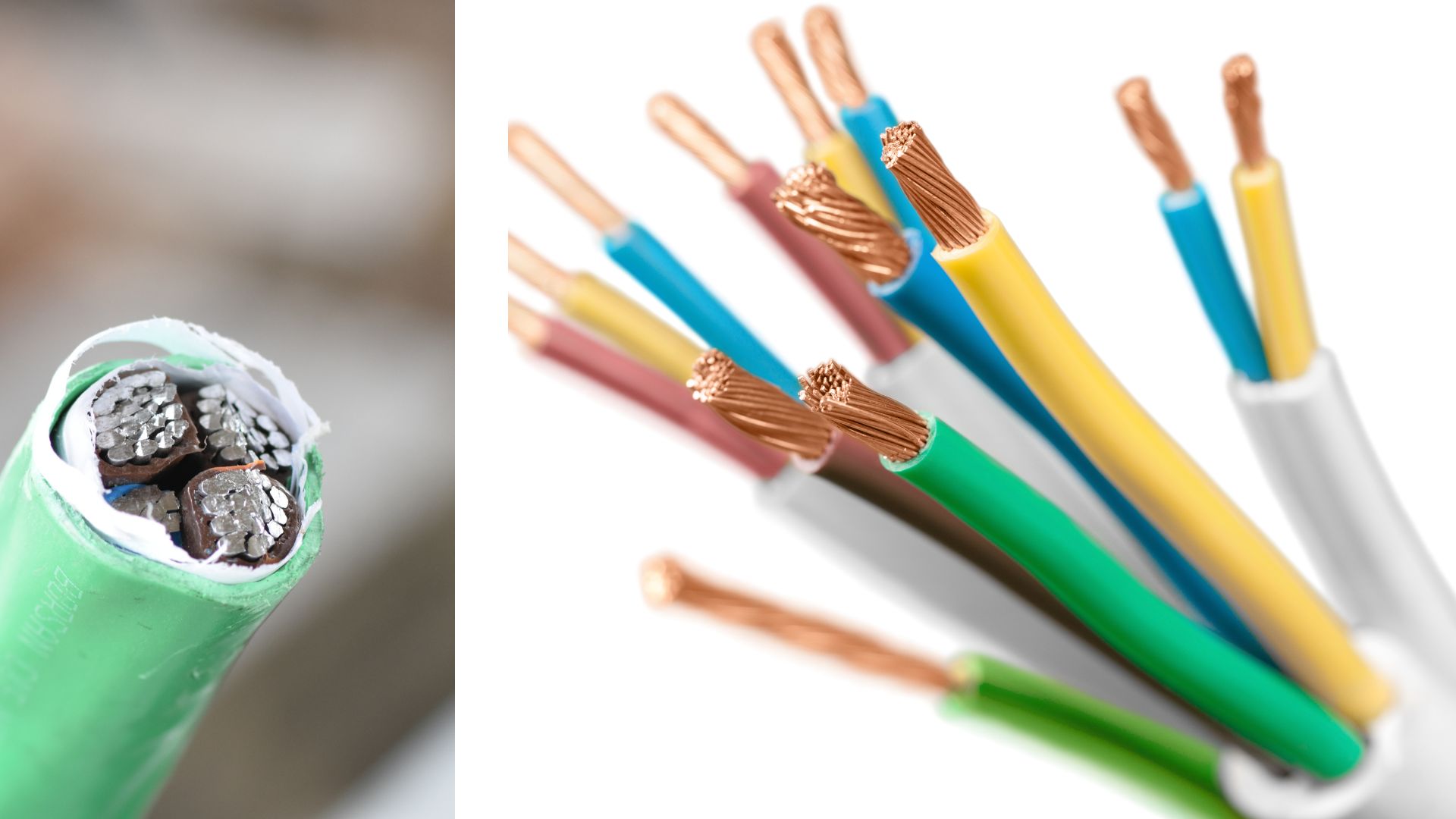

When determining the appropriate wire size for a 100 amp service, it's essential to start with the basics. The most commonly recommended wire gauge for a 100 amp service is 2 AWG copper or 1/0 AWG aluminum. These sizes are designed to handle the current load safely while minimizing the risk of overheating. However, these recommendations are based on standard conditions, and deviations may be necessary depending on your specific circumstances.

For copper wires, a 2 AWG gauge is typically sufficient for a 100 amp service, provided the run length is within 100 feet. Copper is highly conductive, making it an excellent choice for most residential applications. On the other hand, aluminum wires are less conductive, requiring a larger gauge—1/0 AWG—to carry the same current load safely. While aluminum is more cost-effective, it requires careful installation to avoid issues like oxidation and loosening at connection points.

It's important to note that the wire size for 100 amp service isn't a one-size-fits-all solution. Factors such as the distance between the main panel and the subpanel, ambient temperature, and the type of insulation used can all influence the final choice. For example, if your wiring run exceeds 100 feet, you may need to upgrade to a larger gauge to compensate for voltage drop. Always consult a licensed electrician to ensure your wiring meets local codes and safety standards.

Why Does Wire Size Matter for Electrical Safety?

Wire size plays a pivotal role in electrical safety, and understanding its importance can save lives and property. When a wire is too small for the current it carries, it can overheat, leading to insulation breakdown and potentially causing a fire. This is why selecting the correct wire size for a 100 amp service is not just a technicality but a critical safety measure.

Electrical resistance increases with smaller wire sizes, causing more heat to be generated. This heat can degrade the wire's insulation over time, exposing live conductors and increasing the risk of electrical faults. Additionally, undersized wires can lead to voltage drops, which may cause appliances to malfunction or operate inefficiently. For instance, a motor running on low voltage may draw more current to compensate, further exacerbating the problem.

To mitigate these risks, the NEC provides specific guidelines for wire sizing based on ampacity—the maximum current a wire can safely carry. These guidelines take into account factors like wire material, insulation type, and environmental conditions. By adhering to these standards, you ensure that your electrical system operates safely and reliably, protecting both your home and your loved ones.

Read also:Understanding The Connection Between Melania Trump And Vladimir Putin A Comprehensive Insight

Copper vs. Aluminum: Which Material Is Right for You?

Choosing between copper and aluminum wires is one of the most critical decisions when planning a 100 amp service. Both materials have their advantages and drawbacks, and your choice will depend on factors like budget, application, and installation requirements.

Copper wires are renowned for their superior conductivity, making them the preferred choice for most residential applications. They are more durable and resistant to corrosion, ensuring a longer lifespan. Additionally, copper wires can carry the same current load with a smaller gauge compared to aluminum, which can save space and simplify installation. However, the higher cost of copper can be a deterrent for some homeowners.

Aluminum wires, on the other hand, are more affordable and lighter, making them easier to handle during installation. They are often used in larger-scale projects where cost savings are a priority. However, aluminum is less conductive than copper, requiring a larger gauge to achieve the same ampacity. It's also more prone to oxidation and loosening at connection points, which can lead to increased resistance and overheating if not properly installed.

Ultimately, the choice between copper and aluminum comes down to your specific needs and circumstances. If budget is a concern and you're working on a longer run, aluminum may be the better option. However, for shorter runs or applications where safety and longevity are paramount, copper is the clear winner.

How to Calculate Voltage Drop for Your Wire?

Voltage drop is a critical factor to consider when determining the wire size for a 100 amp service. It refers to the reduction in voltage as electricity travels through a conductor, which can affect the performance of your electrical devices. Excessive voltage drop can lead to inefficiencies, increased energy consumption, and even equipment failure.

To calculate voltage drop, you'll need to know the wire's resistance, the current load, and the length of the run. The formula for voltage drop is:

- Voltage Drop = (2 x Wire Length x Current x Resistance) / 1000

For example, if you're using a 2 AWG copper wire with a resistance of 0.194 ohms per 1,000 feet and your run length is 150 feet, the voltage drop at 100 amps would be approximately 5.82 volts. This is within the acceptable range of 3% for most residential applications, but if the run length increases, you may need to upgrade to a larger gauge to maintain efficiency.

Minimizing voltage drop is especially important for appliances like air conditioners, refrigerators, and water heaters, which are sensitive to voltage fluctuations. By carefully calculating voltage drop and selecting the appropriate wire size, you can ensure that your electrical system operates at peak performance.

What Are the National Electrical Code Requirements?

The National Electrical Code (NEC) is the gold standard for electrical safety, providing comprehensive guidelines for wire sizing and installation. Understanding these requirements is essential when determining the wire size for a 100 amp service. The NEC specifies minimum wire gauges based on ampacity, ensuring that wires can handle the current load safely without overheating.

For a 100 amp service, the NEC typically recommends a 2 AWG copper wire or a 1/0 AWG aluminum wire. These recommendations are based on the assumption that the wiring will be installed in a standard environment with an ambient temperature of 30°C (86°F). If your installation involves higher temperatures or bundling multiple wires together, you may need to adjust the wire size accordingly to account for reduced ampacity.

In addition to wire size, the NEC also mandates the use of appropriate insulation types and grounding methods. For example, wires used in wet or damp locations must have moisture-resistant insulation, such as THWN or XHHW. Proper grounding is equally important, as it provides a safe path for electrical current in the event of a fault. Always consult the latest edition of the NEC and work with a licensed electrician to ensure compliance with all applicable codes.

How Does Wire Length Affect Your Choice?

Wire length is a crucial factor when selecting the wire size for a 100 amp service. As the distance between the main panel and the subpanel increases, so does the resistance in the wire. This increased resistance leads to higher voltage drop, which can compromise the performance of your electrical system.

For shorter runs—typically under 100 feet—a 2 AWG copper wire or 1/0 AWG aluminum wire is usually sufficient. However, if your run exceeds this distance, you may need to upgrade to a larger gauge to maintain acceptable voltage levels. For example, a 150-foot run may require a 1 AWG copper wire or a 2/0 AWG aluminum wire to compensate for the increased resistance and voltage drop.

It's also important to consider the type of load you're powering. High-demand appliances like HVAC systems and electric water heaters are particularly sensitive to voltage drop and may require larger wires even for shorter runs. Always perform a voltage drop calculation and consult a professional to ensure your wiring is up to the task.

What Are the Best Practices for Installation?

Proper installation is just as important as selecting the correct wire size for a 100 amp service. Even the best materials can fail if not installed correctly, so it's crucial to follow best practices to ensure safety and compliance.

One of the first steps is to ensure that all connections are secure and free from corrosion. For aluminum wires, this is especially important, as they are more prone to oxidation. Use anti-oxidant compounds on aluminum connections to prevent degradation over time. Additionally, make sure all terminals are rated for the wire material you're using—copper-only terminals should never be used with aluminum wires.

Another best practice is to use conduit for protection, especially in areas where the wiring may be exposed to physical damage or moisture. PVC conduit is a popular choice for residential applications due to its affordability and ease of installation. Metal conduit, while more expensive, offers superior durability and is often required in commercial settings.

Finally, always adhere to local building codes and obtain the necessary permits before beginning your project. A professional inspection can help identify potential issues and ensure that your installation meets all safety standards. By following these best practices, you can enjoy peace of mind knowing that your electrical system is both safe and reliable.

Frequently Asked Questions About Wire Sizing

What Happens If You Use the Wrong Wire Size for 100 Amp Service?

Using the wrong wire size for a 100 amp service can have serious consequences. Undersized wires may overheat, leading to insulation breakdown and fire hazards. On the other hand, oversized wires can be unnecessarily expensive and may not fit properly in terminals or conduits. Always consult the NEC guidelines and a licensed electrician to ensure the correct wire size is used.

Can I Use a Larger Wire Size Than Recommended?

Yes, using a larger wire size than recommended is generally safe and can provide additional benefits, such as reduced voltage drop and improved efficiency. However, it may also increase costs and complicate installation. Always ensure that the terminals and devices you're connecting to are compatible with the larger wire size.

Does the Type of Insulation Affect Wire Size?

Yes, the type of insulation can affect the wire size for a 100 amp service. Different insulation materials have varying temperature ratings, which can impact the wire's ampacity. For example, THHN insulation is rated for higher temperatures than THWN, allowing for smaller wire sizes in certain applications. Always choose insulation that matches

Comprehensive Guide To Sewer Line Protection Plans: What You Need To Know

How Old Is Countess Vaughn? Discover Her Age, Career, And Legacy

Understanding Calories In A Bread Slice: A Comprehensive Guide

Ground Wire Size For 100 Amp Service (Know It Now!) PortablePowerGuides

/electrical-service-size-of-my-home-1152752-01-5bf94b240c25447fb59df3fbec0ef03a.jpg)

100 amp house service wire size Wiring Diagram and Schematics