Choosing The Right Wire Size For 100 Amp Service: A Complete Guide

When it comes to electrical systems, safety and efficiency are paramount, especially when determining the correct wire size for your 100 amp service. Selecting the right wire size is not just about meeting code requirements—it’s about ensuring your home or business operates safely and reliably. Using undersized wires for a 100 amp service can lead to overheating, electrical fires, or frequent circuit breaker trips, while oversized wires may unnecessarily increase costs. Therefore, understanding how big wire for 100 amp service is essential for homeowners, electricians, and contractors alike.

Choosing the appropriate wire size depends on several factors, including the distance from the power source, the material of the wire (copper or aluminum), and the specific electrical load requirements. Copper wires are more conductive and can carry the same current with a smaller diameter compared to aluminum wires, making them a popular choice despite their higher cost. On the other hand, aluminum wires are lighter and more cost-effective but require larger diameters to handle the same load. Understanding these nuances is crucial to making an informed decision that balances safety, performance, and budget.

Additionally, local building codes and National Electrical Code (NEC) guidelines play a significant role in determining wire size for a 100 amp service. These codes are designed to ensure electrical installations are safe and reliable, protecting both property and lives. Whether you’re upgrading an existing electrical system or installing a new one, this guide will walk you through everything you need to know about how big wire for 100 amp service is determined, helping you make the best choice for your needs.

Read also:Is Jackson Mahomes Gay Exploring His Life Career And Public Persona

Table of Contents

- What Factors Determine Wire Size for 100 Amp Service?

- How Does Wire Material Affect Your Choice for 100 Amp Service?

- What Are the Standard Wire Sizes for 100 Amp Service?

- Why Is Voltage Drop Important in Wire Selection?

- How Can You Ensure Code Compliance for 100 Amp Wiring?

- What Are the Common Mistakes to Avoid?

- How to Install Wires for 100 Amp Service Safely?

- FAQs About Wire Size for 100 Amp Service

What Factors Determine Wire Size for 100 Amp Service?

Choosing the correct wire size for a 100 amp service involves evaluating several critical factors. First and foremost, the distance between the electrical panel and the power source plays a significant role. Longer distances require larger wire sizes to compensate for voltage drop, which occurs as electricity travels through the wire. Voltage drop can reduce the efficiency of your electrical system and cause appliances to underperform. For example, if your main panel is located far from the utility meter, you’ll need to account for this when selecting the wire gauge.

Another important consideration is the type of load your system will handle. Homes with high-power appliances, such as electric furnaces, water heaters, or central air conditioning units, may require thicker wires to handle the increased electrical demand. Additionally, the environment where the wires will be installed matters. Wires exposed to extreme temperatures, moisture, or direct sunlight may need special insulation or a larger size to ensure durability and performance.

Finally, the method of installation can influence wire size. For instance, wires running through conduits may generate more heat due to restricted airflow, requiring larger diameters to prevent overheating. Understanding these factors will help you determine the appropriate wire size for your 100 amp service, ensuring both safety and efficiency.

How Does Wire Material Affect Your Choice for 100 Amp Service?

The material of the wire is one of the most critical factors in determining how big wire for 100 amp service should be. Copper and aluminum are the two most common materials used for electrical wiring, each with its own advantages and limitations. Copper is highly conductive, meaning it can carry more current with a smaller diameter compared to aluminum. This makes copper wires ideal for installations where space is limited or where higher efficiency is required.

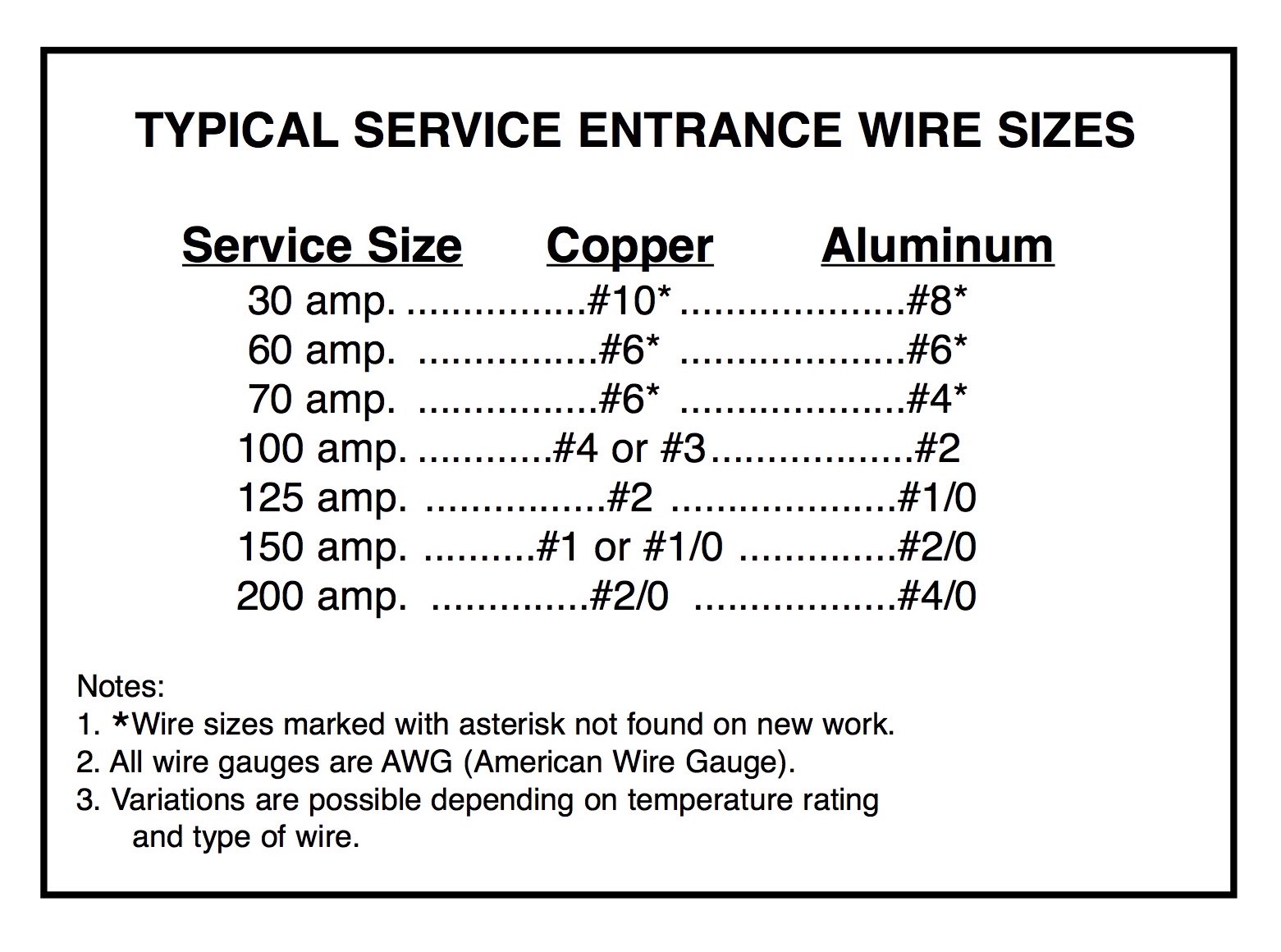

Aluminum, on the other hand, is lighter and less expensive, making it a popular choice for large-scale installations or projects with budget constraints. However, aluminum wires have higher resistance, which means they require a larger diameter to handle the same electrical load as copper. For a 100 amp service, this typically translates to using a 2/0 AWG aluminum wire compared to a 3 AWG copper wire. It’s essential to weigh these factors carefully when selecting the material for your wiring project.

Advantages of Copper Wiring

- Higher conductivity and efficiency

- Smaller diameter for the same current capacity

- More resistant to corrosion and oxidation

Advantages of Aluminum Wiring

- Cost-effective for large installations

- Lightweight and easier to handle

- Suitable for long-distance runs where weight matters

What Are the Standard Wire Sizes for 100 Amp Service?

When it comes to how big wire for 100 amp service should be, the National Electrical Code (NEC) provides clear guidelines. For copper wires, a 3 AWG gauge is typically recommended for a 100 amp service. This size ensures safe and efficient operation while minimizing voltage drop. For aluminum wires, a 2/0 AWG gauge is the standard choice due to their lower conductivity. These sizes are designed to handle the maximum current load of 100 amps without overheating or causing safety hazards.

Read also:Dawn Wells Measurements A Complete Guide To Her Life And Career

It’s important to note that these recommendations assume a typical installation with moderate distances between the power source and the electrical panel. If your setup involves longer distances or unique environmental conditions, you may need to adjust the wire size accordingly. Consulting a professional electrician or referring to NEC tables can help you make an informed decision tailored to your specific needs.

Factors Influencing Wire Size Adjustments

- Distance between the power source and the panel

- Presence of high-power appliances

- Environmental conditions like temperature and moisture

Why Is Voltage Drop Important in Wire Selection?

Voltage drop is a critical consideration when determining how big wire for 100 amp service needs to be. Voltage drop occurs when electricity travels through a wire, causing a reduction in voltage due to resistance. Excessive voltage drop can lead to inefficiencies, such as dimming lights, underperforming appliances, and even damage to sensitive electronics. To mitigate these issues, it’s essential to choose a wire size that minimizes voltage drop while maintaining safety and performance.

For a 100 amp service, the NEC recommends keeping voltage drop below 3% for optimal performance. This can be achieved by selecting the appropriate wire gauge based on the distance between the power source and the electrical panel. For example, if the distance exceeds 100 feet, you may need to upgrade to a larger wire size to compensate for the increased resistance. Calculating voltage drop involves understanding the wire’s resistance per foot, the current load, and the total length of the wire run.

How to Calculate Voltage Drop

- Determine the wire’s resistance per foot (available in NEC tables)

- Multiply the resistance by the total length of the wire run

- Multiply the result by the current load (in amps)

- Compare the voltage drop percentage to the 3% threshold

How Can You Ensure Code Compliance for 100 Amp Wiring?

Ensuring code compliance is a non-negotiable aspect of any electrical installation, including determining how big wire for 100 amp service should be. The NEC provides detailed guidelines on wire sizing, material selection, and installation practices to ensure safety and reliability. Adhering to these standards not only protects your property but also ensures that your installation passes inspections and meets insurance requirements.

To ensure compliance, start by consulting the latest edition of the NEC, which outlines specific requirements for wire sizes based on current load, distance, and material. Additionally, local building codes may impose additional requirements, so it’s essential to verify these with your municipality or a licensed electrician. Proper documentation, such as permits and inspection reports, is also crucial to demonstrate compliance and avoid potential legal issues.

Steps to Ensure Code Compliance

- Refer to the NEC tables for wire size recommendations

- Verify local building codes and permit requirements

- Hire a licensed electrician for complex installations

What Are the Common Mistakes to Avoid?

Even experienced electricians can make mistakes when determining how big wire for 100 amp service should be. One common error is underestimating the importance of voltage drop, leading to undersized wires that compromise performance. Another frequent mistake is failing to account for the specific material of the wire, as aluminum requires larger diameters than copper for the same load.

Improper installation practices, such as failing to secure wires properly or neglecting environmental factors, can also lead to safety hazards. Additionally, skipping inspections or failing to obtain the necessary permits can result in costly fines or even legal action. By being aware of these pitfalls, you can avoid common mistakes and ensure a safe and efficient installation.

Common Installation Mistakes

- Using undersized wires for long-distance runs

- Ignoring environmental conditions like moisture or heat

- Skipping professional inspections and permits

How to Install Wires for 100 Amp Service Safely?

Installing wires for a 100 amp service requires careful planning and execution to ensure safety and compliance. Start by turning off the main power supply to avoid electrical hazards during installation. Next, measure the distance between the power source and the electrical panel to determine the appropriate wire size. For copper wires, a 3 AWG gauge is typically sufficient, while aluminum wires require a 2/0 AWG gauge for the same load.

Once the wires are selected, route them through conduits or secure them properly if running through open spaces. Ensure that all connections are tight and free of corrosion, as loose connections can lead to overheating and potential fire hazards. Finally, schedule an inspection with a certified electrician to verify that the installation meets all safety and code requirements.

Safety Tips for Wire Installation

- Always turn off the main power before starting

- Use proper tools and equipment for cutting and stripping wires

- Secure wires to prevent movement or damage

FAQs About Wire Size for 100 Amp Service

What Happens If You Use a Wire That’s Too Small for 100 Amp Service?

Using a wire that’s too small for a 100 amp service can lead to overheating, increased resistance, and potential fire hazards. It’s crucial to select the correct wire size based on the load and distance to ensure safety and efficiency.

Can I Use Aluminum Wire Instead of Copper for 100 Amp Service?

Yes, you can use aluminum wire, but it requires a larger gauge (2/0 AWG) compared to copper (3 AWG) to handle the same current load. Aluminum is cost-effective but less conductive, so proper sizing is essential.

How Do I Know If My Existing Wiring Can Handle 100 Amp Service?

To determine if your existing wiring can handle 100 amp service, check the wire gauge and material. Copper wires should be at least 3 AWG, while aluminum wires should be 2/0 AWG. Consulting a licensed electrician is recommended for accurate assessment.

Conclusion

Choosing the right wire size for a

How Much Has JB Mauney Net Worth Grown Over The Years?

Top 10 Ways To See If Gold Is Real: A Comprehensive Guide

What Is Nihong Meaning? Exploring The Depths Of Japanese Language And Culture

Direct Burial Wire 100 Amp Service Houses & Apartments For Rent

Ground Wire For 100 Amp Service