What Is The Best Wire Size For 10 Amp? A Complete Guide

Whether you’re wiring a new appliance, setting up a workshop, or upgrading your home’s electrical system, understanding the appropriate wire gauge can prevent overheating, reduce the risk of fire, and ensure your devices operate efficiently. Electrical systems are complex, but with the right knowledge, you can make informed decisions that align with safety standards and practical needs. When working with a 10-amp load, the wire gauge you select must balance current-carrying capacity with the length of the circuit. For short runs, a thinner wire may suffice, but longer distances require thicker wires to minimize voltage drop and maintain optimal performance. Copper is the most commonly used material due to its excellent conductivity, but aluminum wires are also an option in specific scenarios. The National Electrical Code (NEC) provides guidelines for wire sizing, ensuring compliance with safety regulations. This article dives deep into everything you need to know about wire size for 10 amp applications, from understanding wire gauges and materials to practical tips for installation. By the end, you’ll have a comprehensive understanding of how to select the right wire for your needs, ensuring both safety and efficiency in your electrical projects.

Table of Contents

- What is the Best Wire Size for 10 Amp?

- Why Does Wire Size Matter for 10 Amp Circuits?

- How Do You Calculate the Right Wire Size for 10 Amp?

- What Are the Different Types of Wires for 10 Amp?

- Is There a Difference Between Copper and Aluminum Wires for 10 Amp?

- What Are Common Mistakes When Selecting Wire Size for 10 Amp?

- How Can You Ensure Safety with Wire Size for 10 Amp?

- Frequently Asked Questions About Wire Size for 10 Amp

What is the Best Wire Size for 10 Amp?

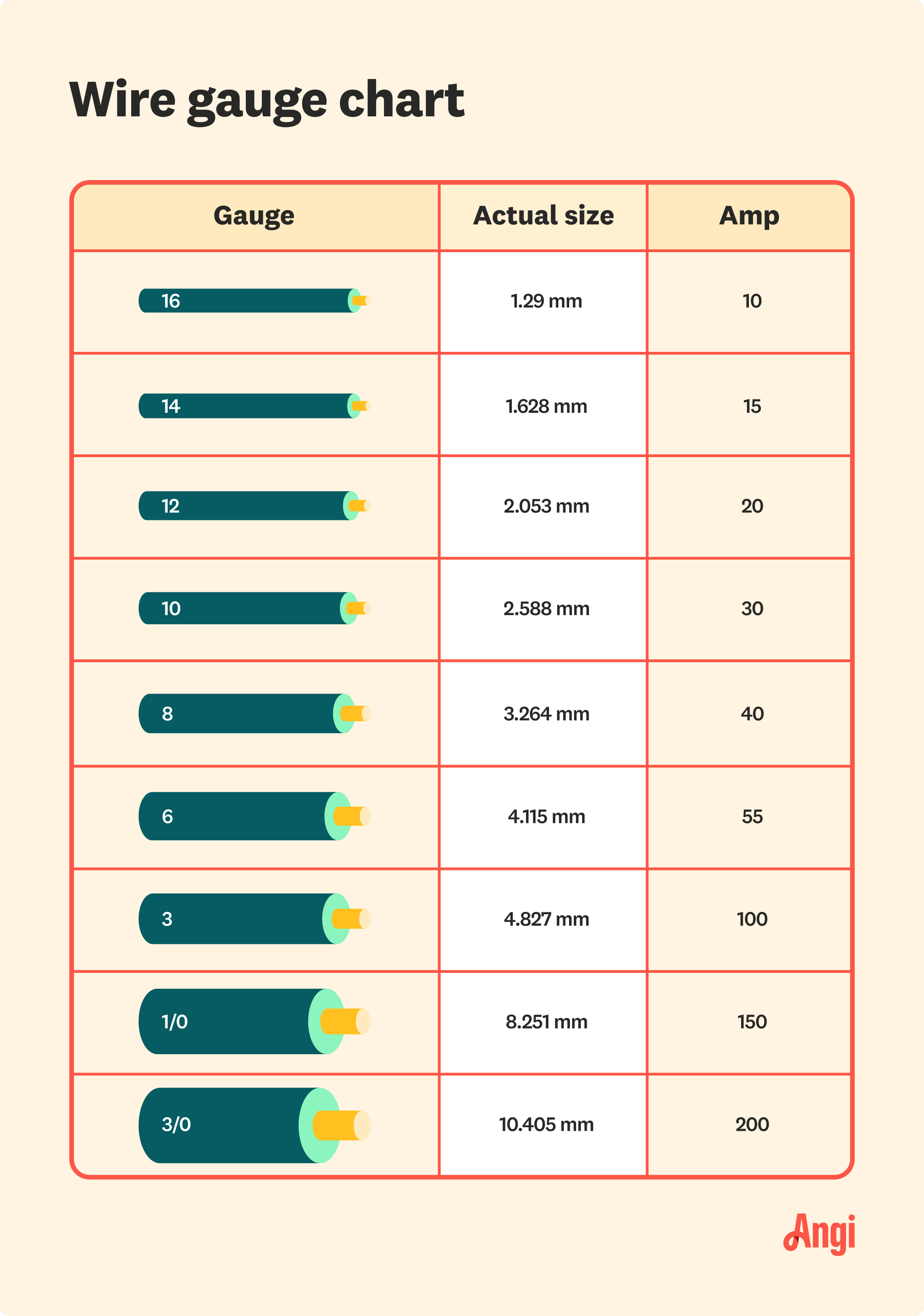

For most 10-amp applications, a 16-gauge wire is the standard recommendation. This wire size is ideal for short runs and standard household circuits. However, the actual wire size can vary depending on factors like the length of the circuit, the type of insulation, and the ambient temperature. For example, if you’re running a circuit over a longer distance, you might need to upgrade to a 14-gauge wire to compensate for voltage drop.

It’s important to note that wire size is measured using the American Wire Gauge (AWG) system. In this system, a lower gauge number indicates a thicker wire. For instance, a 14-gauge wire is thicker than a 16-gauge wire, allowing it to carry more current without overheating. When selecting wire size for 10 amp, always consider the specific requirements of your project and consult the NEC guidelines for further clarity.

Read also:What Are Examples A Comprehensive Guide To Understanding And Using Examples Effectively

Additionally, the type of insulation plays a role in determining the appropriate wire size. Wires with higher temperature ratings, such as THHN or THWN, can handle more current than those with lower ratings. This flexibility allows you to choose a wire that matches both your current needs and environmental conditions.

Why Does Wire Size Matter for 10 Amp Circuits?

Choosing the correct wire size for 10 amp circuits is not just a matter of compliance; it’s a safety imperative. Wires that are too thin for the current they carry can overheat, leading to insulation damage, electrical fires, or even complete circuit failure. On the other hand, using excessively thick wires can be unnecessarily costly and cumbersome, especially for small-scale projects.

One of the primary reasons wire size matters is voltage drop. Voltage drop occurs when the resistance in a wire causes a reduction in voltage as electricity travels through the circuit. This can lead to inefficient operation of appliances and devices, as they may not receive the full voltage required for optimal performance. For 10-amp circuits, ensuring minimal voltage drop is essential, especially for long runs.

Another consideration is the material of the wire. Copper wires are preferred for their superior conductivity and durability, but they are more expensive than aluminum wires. Aluminum, while cost-effective, has higher resistance, meaning you may need a larger gauge to achieve the same performance as copper. Understanding these nuances helps you make informed decisions when selecting wire size for 10 amp applications.

Key Factors Influencing Wire Size Selection

- Current Load: The wire must handle the full 10-amp load without overheating.

- Distance: Longer runs require thicker wires to reduce voltage drop.

- Temperature: High ambient temperatures may necessitate a larger wire size.

- Insulation Type: Wires with higher temperature ratings can carry more current.

How Do You Calculate the Right Wire Size for 10 Amp?

Calculating the correct wire size for 10 amp involves understanding the relationship between current, distance, and voltage drop. The first step is to determine the maximum allowable voltage drop, which is typically around 3% for most household circuits. Using this value, you can calculate the appropriate wire gauge based on the length of the circuit.

For example, if you’re running a 10-amp circuit over 50 feet, a 16-gauge wire might suffice. However, if the distance increases to 100 feet, you may need to upgrade to a 14-gauge wire to maintain acceptable voltage levels. Online calculators and NEC charts can simplify this process by providing pre-determined wire sizes based on specific conditions.

Read also:Baryshnikov The Legendary Dancer Who Redefined Ballet

Another factor to consider is the type of load. Inductive loads, such as motors, require more robust wiring compared to resistive loads like heaters. Understanding the nature of your load helps you fine-tune your wire size selection, ensuring both safety and efficiency.

Steps to Calculate Wire Size

- Determine the circuit’s current load (10 amps).

- Measure the length of the circuit in feet.

- Calculate the allowable voltage drop (usually 3%).

- Refer to NEC charts or online calculators for the appropriate wire gauge.

What Are the Different Types of Wires for 10 Amp?

When selecting wire size for 10 amp, it’s essential to consider the type of wire insulation and its application. Common types include THHN, THWN, and NM-B cables. THHN and THWN wires are often used in conduit installations, while NM-B cables are typical in residential wiring. Each type has specific temperature and moisture resistance ratings, making them suitable for different environments.

For outdoor applications, wires with moisture-resistant insulation, such as THWN, are ideal. These wires can withstand exposure to water and humidity without degrading. Conversely, indoor circuits often use THHN or NM-B cables, which are less expensive and easier to install. The choice of wire type should align with both the environmental conditions and the specific requirements of your project.

Another consideration is stranded versus solid wire. Stranded wires are more flexible and easier to route through tight spaces, making them ideal for complex installations. Solid wires, on the other hand, are more rigid and better suited for straightforward runs. Both options are available in various gauges, including those suitable for 10-amp circuits.

Comparison of Wire Types

| Type | Application | Temperature Rating | Moisture Resistance |

|---|---|---|---|

| THHN | Conduit installations | 90°C | No |

| THWN | Outdoor use | 75°C | Yes |

| NM-B | Residential wiring | 60°C | No |

Is There a Difference Between Copper and Aluminum Wires for 10 Amp?

Yes, there is a significant difference between copper and aluminum wires when selecting wire size for 10 amp. Copper wires are more conductive, durable, and resistant to corrosion, making them the preferred choice for most applications. However, they are also more expensive, which is why aluminum wires are sometimes used as a cost-effective alternative.

Aluminum wires have higher resistance compared to copper, meaning they require a larger gauge to carry the same current safely. For example, a 14-gauge aluminum wire may be needed to handle the same 10-amp load that a 16-gauge copper wire can manage. Additionally, aluminum wires are more prone to oxidation, which can lead to connection issues over time if not properly maintained.

When choosing between copper and aluminum, consider the long-term costs and maintenance requirements. While aluminum may save money upfront, copper’s superior performance and longevity often make it the better investment for 10-amp circuits.

Pros and Cons of Copper vs. Aluminum Wires

- Copper: Higher conductivity, more durable, resistant to corrosion, but expensive.

- Aluminum: Cost-effective, lighter, but less conductive and prone to oxidation.

What Are Common Mistakes When Selecting Wire Size for 10 Amp?

One common mistake when selecting wire size for 10 amp is underestimating the importance of voltage drop. Many people assume that a wire rated for 10 amps will perform adequately regardless of the circuit length. However, longer runs require thicker wires to maintain voltage levels, and ignoring this can lead to inefficiency and potential damage to connected devices.

Another frequent error is using the wrong type of insulation for the environment. For instance, using a non-moisture-resistant wire in an outdoor setting can result in rapid degradation and safety hazards. Always choose wires with insulation that matches the installation conditions, whether indoor, outdoor, or in conduit.

Lastly, failing to consult the NEC guidelines is a critical oversight. These guidelines provide standardized recommendations for wire size, insulation, and installation practices, ensuring compliance with safety standards. Skipping this step can lead to non-compliance and increased risk of electrical issues.

How to Avoid These Mistakes

- Always account for voltage drop when calculating wire size.

- Choose insulation types based on environmental conditions.

- Refer to NEC guidelines for standardized recommendations.

How Can You Ensure Safety with Wire Size for 10 Amp?

Ensuring safety when selecting wire size for 10 amp involves a combination of proper planning, adherence to guidelines, and regular maintenance. Start by consulting the NEC to determine the appropriate wire gauge for your specific application. This ensures that your wiring meets industry standards and reduces the risk of overheating or fire.

Next, always use wires with the correct insulation type and temperature rating. For example, if your circuit will be exposed to high temperatures, choose wires rated for such conditions. Additionally, ensure that all connections are secure and free from corrosion, as loose or corroded connections can lead to overheating and failure.

Finally, consider hiring a licensed electrician for complex installations. While DIY projects can be cost-effective, professional expertise ensures that your wiring is safe, compliant, and optimized for performance. Regular inspections and maintenance further enhance

How Much Has JB Mauney Net Worth Grown Over The Years?

Wheat Bread Vs White Bread Calories: Which Is Healthier For You?

Understanding Calories For White Bread: Nutrition, Health, And More

Silicone wire size vs withstand current (wire amp chart) esk8.news

What Is the Correct Wire Size for 100Amp Service? Angi