What Is The Ideal Wire Size For A 100 Amp Service?

Choosing the right wire size for a 100 amp service is critical to ensuring the safety and efficiency of your electrical system. Whether you're installing a new electrical panel or upgrading an existing one, understanding the appropriate wire gauge is essential. A 100 amp service is common in residential homes, and using the correct wire size prevents overheating, voltage drops, and potential fire hazards. Many homeowners and electricians often wonder about the ideal wire gauge, insulation type, and material to use for such installations. This article will provide a comprehensive guide to help you make informed decisions and ensure compliance with electrical codes.

When it comes to wire size for a 100 amp service, several factors come into play, including the distance from the power source, the material of the wire (copper or aluminum), and the type of insulation. Copper wires are typically preferred for their superior conductivity, but aluminum is a cost-effective alternative. Additionally, the National Electrical Code (NEC) provides specific guidelines to ensure safe installations. Understanding these factors is crucial for anyone involved in electrical work, whether you're a DIY enthusiast or a professional electrician.

As we delve deeper into this topic, you'll learn about the various wire gauges suitable for a 100 amp service, how to calculate voltage drop, and the importance of proper grounding. We'll also explore common mistakes to avoid and answer frequently asked questions about wire sizing. By the end of this article, you'll have a clear understanding of how to select the right wire size for your 100 amp service, ensuring both safety and compliance with industry standards.

Read also:Understanding The Connection Between Melania Trump And Vladimir Putin A Comprehensive Insight

Table of Contents

- What Factors Determine the Wire Size for a 100 Amp Service?

- How Do You Calculate the Right Wire Gauge for a 100 Amp Service?

- What Are the Differences Between Copper and Aluminum Wires for a 100 Amp Service?

- Why Is Proper Insulation Important for a 100 Amp Service Wire?

- How Can You Avoid Common Mistakes When Selecting Wire Size?

- What Are the National Electrical Code Requirements for a 100 Amp Service?

- How Does Distance Affect the Wire Size for a 100 Amp Service?

- What Are the Best Practices for Grounding a 100 Amp Service?

What Factors Determine the Wire Size for a 100 Amp Service?

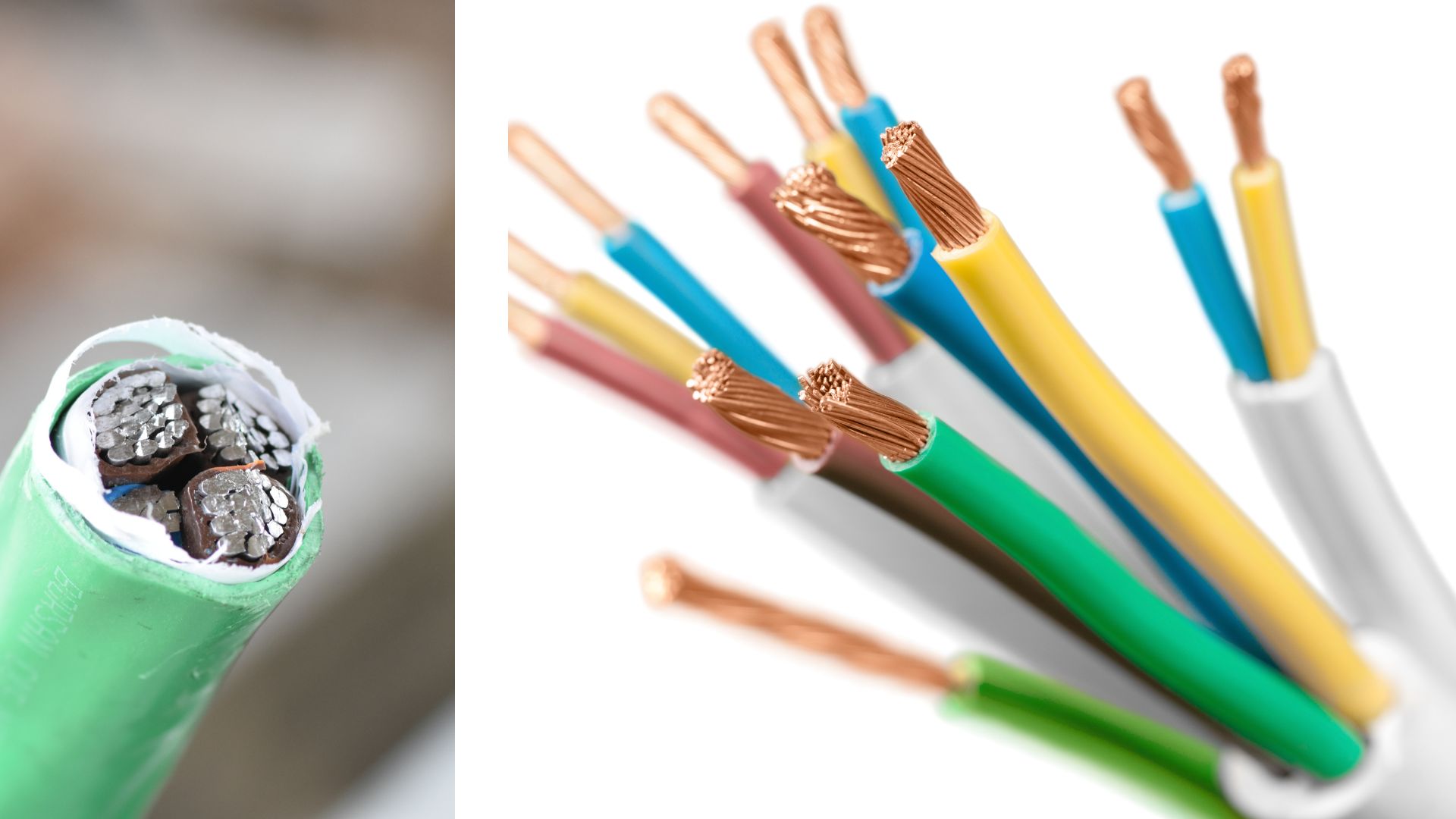

Selecting the correct wire size for a 100 amp service involves considering multiple factors that influence electrical performance and safety. One of the primary considerations is the material of the wire. Copper wires are highly conductive and require a smaller gauge compared to aluminum wires for the same current-carrying capacity. For instance, a 100 amp service typically requires a 2-gauge copper wire, while a 1/0-gauge aluminum wire is necessary to achieve the same performance.

Another crucial factor is the length of the wire run. Longer distances between the power source and the electrical panel result in voltage drop, which can affect the efficiency of your electrical system. To mitigate this, you may need to increase the wire gauge to compensate for the additional resistance. For example, if your service panel is located more than 100 feet from the meter, upgrading to a thicker wire, such as 1-gauge copper or 2/0-gauge aluminum, is advisable.

Environmental conditions also play a role in determining wire size for a 100 amp service. If the wires are exposed to high temperatures or moisture, you may need to choose wires with specific insulation types, such as THHN or XHHW, which are designed to withstand harsh conditions. Additionally, local building codes and regulations may dictate the minimum wire size required for safety and compliance. Consulting with a licensed electrician or referring to the NEC guidelines can help ensure that your installation meets all necessary standards.

Why Does Wire Material Matter?

The material of the wire directly impacts its conductivity and overall performance. Copper is the preferred choice for most residential applications due to its excellent electrical conductivity and durability. It can carry more current than aluminum at a smaller gauge, making it ideal for tight spaces. However, copper wires are more expensive, which is why aluminum is often used as a cost-effective alternative.

Aluminum wires, while less conductive, are lighter and easier to work with in certain scenarios. However, they require larger gauges to handle the same current load as copper. For example, a 1/0-gauge aluminum wire is equivalent in performance to a 2-gauge copper wire for a 100 amp service. It's essential to weigh the pros and cons of each material based on your budget, installation requirements, and long-term maintenance considerations.

How Does Insulation Affect Wire Performance?

Insulation is another critical factor that affects the wire size for a 100 amp service. Proper insulation ensures that the wire can safely carry the required current without overheating or causing electrical hazards. Different insulation types, such as THHN, THWN, and XHHW, are designed for specific applications and environments.

Read also:Understanding Steve Dulcichs Illness A Comprehensive Guide

For instance, THHN insulation is commonly used for dry indoor environments, while XHHW is better suited for wet or damp conditions. Choosing the wrong insulation type can lead to premature wear and potential safety risks. Always ensure that the insulation rating matches the intended use of the wire and complies with local building codes.

How Do You Calculate the Right Wire Gauge for a 100 Amp Service?

Calculating the right wire gauge for a 100 amp service involves understanding the relationship between current, voltage drop, and wire resistance. The NEC provides guidelines for maximum allowable voltage drop, typically recommending no more than a 3% drop for branch circuits and 5% for feeders. Exceeding these limits can lead to inefficient electrical performance and potential damage to appliances.

To calculate the voltage drop, you can use the formula: Voltage Drop = (2 x Length x Current x Resistance) / 1000. Here, "Length" refers to the distance in feet, "Current" is the amperage (100 amps in this case), and "Resistance" depends on the wire gauge and material. For example, a 2-gauge copper wire has a resistance of approximately 0.194 ohms per 1,000 feet, while a 1/0-gauge aluminum wire has a resistance of about 0.122 ohms per 1,000 feet.

Let's consider an example: If your service panel is 150 feet away from the meter, using a 2-gauge copper wire would result in a voltage drop of approximately 5.82 volts (2 x 150 x 100 x 0.194 / 1000). This is within the acceptable range of 3% for a 240-volt system. However, if the distance increases to 200 feet, upgrading to a 1-gauge copper wire or 2/0-gauge aluminum wire may be necessary to maintain performance.

What Tools Can Help You Calculate Wire Size?

Several online calculators and mobile apps are available to simplify the process of determining the right wire size for a 100 amp service. These tools allow you to input variables such as distance, current, and wire material to get accurate recommendations. Additionally, consulting with a licensed electrician can provide personalized advice based on your specific installation requirements.

What Are the Differences Between Copper and Aluminum Wires for a 100 Amp Service?

Copper and aluminum wires each have their own advantages and disadvantages when used for a 100 amp service. Understanding these differences is crucial for making an informed decision about which material to choose for your electrical system.

Copper wires are known for their superior conductivity and durability. They can carry more current than aluminum at a smaller gauge, making them ideal for installations where space is limited. For example, a 2-gauge copper wire is sufficient for a 100 amp service, while aluminum requires a 1/0-gauge wire to achieve the same performance. Copper is also less prone to corrosion, ensuring long-term reliability and safety.

On the other hand, aluminum wires are lighter and more cost-effective, making them a popular choice for larger installations. However, they require larger gauges to handle the same current load as copper, and they are more susceptible to oxidation and corrosion over time. Proper installation techniques, such as using anti-oxidant compounds and ensuring secure connections, are essential to mitigate these risks.

What Are the Cost Implications of Each Material?

Cost is often a deciding factor when choosing between copper and aluminum wires for a 100 amp service. Copper wires are generally more expensive upfront, but their durability and performance can result in long-term savings. Aluminum wires, while cheaper initially, may require more frequent maintenance and replacements, especially in harsh environments.

Why Is Proper Insulation Important for a 100 Amp Service Wire?

Proper insulation is vital for ensuring the safety and efficiency of wires used in a 100 amp service. Insulation not only protects the wire from external elements but also prevents electrical hazards such as short circuits and overheating. Choosing the right insulation type depends on the environment and application of the wire.

For indoor installations, THHN insulation is commonly used due to its resistance to heat and moisture. In contrast, XHHW insulation is better suited for outdoor or underground applications, as it can withstand exposure to water and extreme temperatures. Always ensure that the insulation rating matches the intended use of the wire and complies with local building codes.

What Are the Risks of Poor Insulation?

Poor insulation can lead to several risks, including overheating, voltage drop, and potential fire hazards. It's essential to inspect wires regularly for signs of wear or damage and replace them as needed to maintain safety and performance.

How Can You Avoid Common Mistakes When Selecting Wire Size?

When selecting wire size for a 100 amp service, several common mistakes can compromise safety and efficiency. One frequent error is underestimating the importance of voltage drop, which can lead to inefficient electrical performance and potential damage to appliances. Always calculate the voltage drop based on the distance and wire material to ensure optimal performance.

Another mistake is choosing the wrong insulation type for the environment. For example, using THHN insulation in a wet or damp location can result in premature wear and potential safety risks. Always select insulation that matches the intended use of the wire and complies with local building codes.

What Are the Consequences of Incorrect Wire Sizing?

Incorrect wire sizing can lead to overheating, voltage drop, and potential fire hazards. It's crucial to consult with a licensed electrician or refer to the NEC guidelines to ensure that your installation meets all necessary standards.

What Are the National Electrical Code Requirements for a 100 Amp Service?

The National Electrical Code (NEC) provides specific guidelines for wire size and installation requirements for a 100 amp service. These guidelines are designed to ensure safety and compliance with industry standards. For example, the NEC requires that wires used for a 100 amp service have a minimum gauge of 2 for copper and 1/0 for aluminum.

Additionally, the NEC mandates proper grounding and bonding to prevent electrical hazards. Grounding ensures that excess electricity is safely directed into the earth, protecting both the electrical system and the occupants of the building. Always refer to the latest edition of the NEC for the most up-to-date requirements and recommendations.

How Do Local Codes Differ from NEC Guidelines?

While the NEC provides a baseline for electrical safety, local building codes may have additional requirements or variations. It's essential to consult with local authorities or a licensed electrician to ensure compliance with all applicable regulations.

Unlocking The Secrets Of Bread Nutrition: A Comprehensive Guide

Understanding How Much Calories In A Bread Slice: A Comprehensive Guide

Discover The Ultimate Golf Experience At Vanillagoft.com: Your Gateway To Golfing Excellence

Ground Wire Size For 100 Amp Service (Know It Now!) PortablePowerGuides

/electrical-service-size-of-my-home-1152752-01-5bf94b240c25447fb59df3fbec0ef03a.jpg)

100 amp house service wire size Wiring Diagram and Schematics