What Size Of Wire For 100 Amp: A Comprehensive Guide For Electrical Safety

When it comes to electrical wiring, precision is key. A 100-amp service is a common setup for many residential and commercial properties, but the wire size required can vary depending on several factors. These include the material of the wire (copper or aluminum), the length of the circuit, and the temperature conditions in which the wire will operate. For example, copper wires are more conductive and can often be smaller in diameter than aluminum wires for the same current load. Similarly, longer runs may require thicker wires to compensate for voltage drop. Understanding these nuances is crucial to avoid potential hazards and ensure compliance with the National Electrical Code (NEC). Beyond safety, selecting the correct wire size also has practical implications. Properly sized wires reduce energy loss, improve system performance, and extend the lifespan of your electrical equipment. Whether you’re a homeowner planning a DIY project or a professional electrician, this article will provide you with all the insights you need to determine the ideal wire size for a 100-amp service. From understanding the basics of electrical wiring to exploring advanced considerations, we’ve got you covered. Let’s dive in and unravel the complexities of what size of wire for 100 amp.

Table of Contents

- Why Does Wire Size Matter for 100-Amp Service?

- What Are the Standard Wire Sizes for 100-Amp?

- What Are the Key Factors in Choosing the Right Wire?

- How to Calculate Voltage Drop for 100-Amp Service?

- What Are the NEC Guidelines for 100-Amp Wiring?

- Common Mistakes to Avoid When Selecting Wire Size

- Frequently Asked Questions About Wire Sizing

- Conclusion: Making the Right Choice for 100-Amp Wiring

Why Does Wire Size Matter for 100-Amp Service?

When it comes to electrical systems, wire size is a fundamental consideration that directly affects performance and safety. For a 100-amp service, the wire must be capable of handling the current load without overheating. If the wire is too small, it can lead to excessive resistance, which generates heat and increases the risk of electrical fires. On the other hand, a wire that’s too large might be unnecessarily expensive and cumbersome to install. Understanding the importance of wire size ensures that your electrical system operates safely and efficiently.

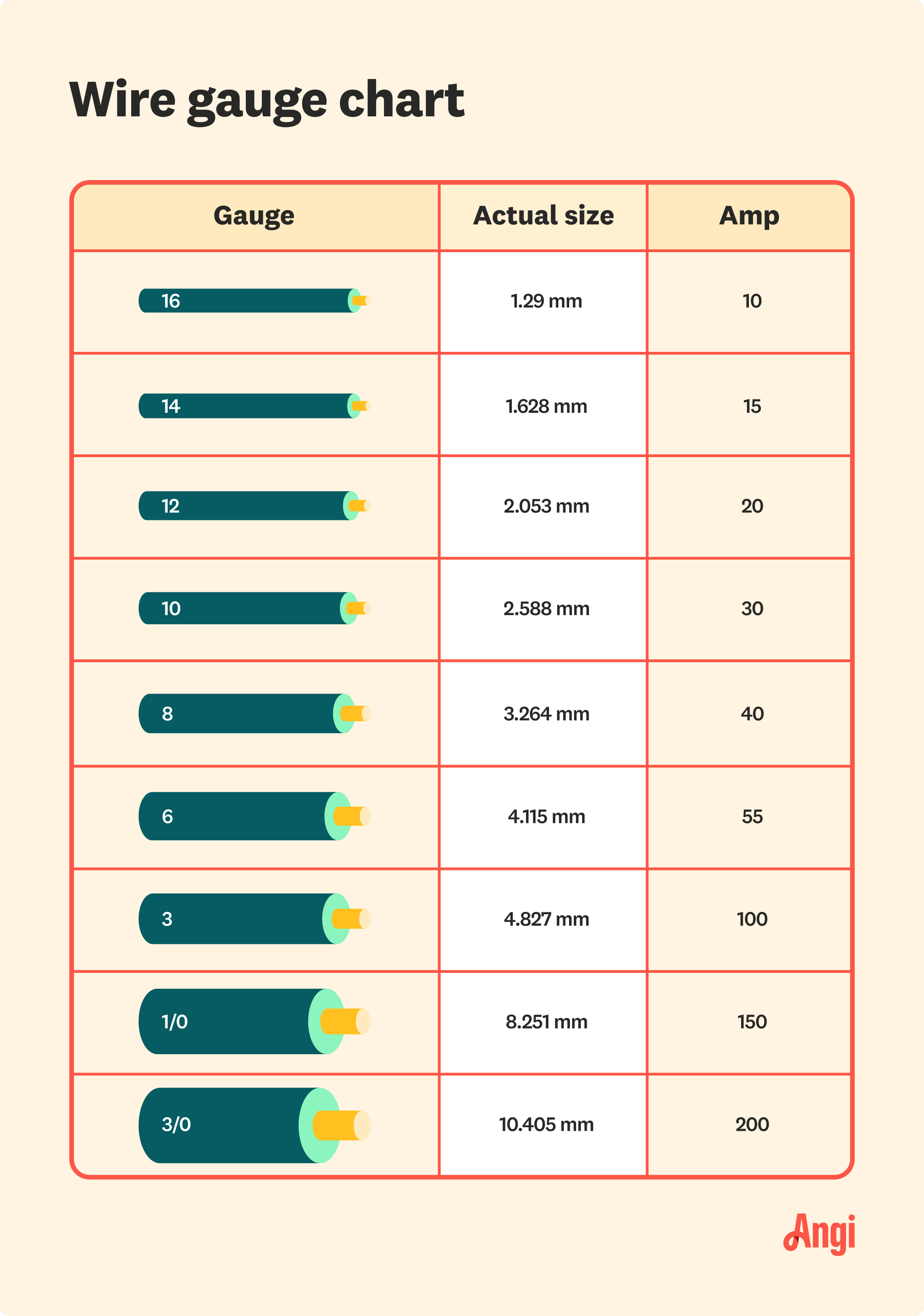

The size of the wire is determined by its gauge, which refers to the diameter of the conductor. In general, the smaller the gauge number, the thicker the wire. For a 100-amp service, the most common wire sizes are 2 AWG copper or 1/0 AWG aluminum. These sizes are designed to handle the current load while minimizing voltage drop and heat buildup. However, these recommendations can vary based on the specific circumstances of your installation, such as the length of the wire run and the material used.

Read also:Exploring Adam Savages Children A Glimpse Into Their Lives And Influence

Beyond the immediate safety concerns, using the correct wire size also has long-term benefits. Properly sized wires reduce energy loss, which can lead to lower electricity bills and improved system performance. Additionally, they help extend the lifespan of your electrical equipment by preventing excessive wear and tear. By prioritizing the right wire size, you’re not only ensuring compliance with safety standards but also making a smart investment in the longevity of your electrical system.

What Are the Standard Wire Sizes for 100-Amp?

When determining what size of wire for 100 amp service is appropriate, it’s important to consider the standard options available. For copper wires, 2 AWG is typically the minimum size recommended for a 100-amp service. Copper is highly conductive, which means it can carry more current with a smaller diameter compared to other materials. For aluminum wires, which are less conductive, a larger size is required—usually 1/0 AWG. These standards are based on the National Electrical Code (NEC) guidelines, which ensure safety and efficiency in electrical installations.

However, these recommendations are not one-size-fits-all. The actual wire size you need may vary depending on factors such as the length of the circuit and the environmental conditions. For instance, longer runs may require thicker wires to compensate for voltage drop, while installations in high-temperature environments may also necessitate larger wire sizes. Understanding these variables is key to selecting the right wire for your specific needs.

Copper vs. Aluminum Wire: Which Is Better?

One of the most common debates in electrical wiring is whether copper or aluminum wire is the better choice. Copper is widely regarded as the superior option due to its higher conductivity, flexibility, and resistance to corrosion. These properties make it ideal for a wide range of applications, including 100-amp services. However, copper is also more expensive, which can be a limiting factor for some projects.

Aluminum, on the other hand, is more affordable and lighter, making it easier to handle during installation. However, it has lower conductivity, which means larger wire sizes are required to carry the same current as copper. Additionally, aluminum is more prone to corrosion and requires special connectors to prevent oxidation. Ultimately, the choice between copper and aluminum depends on your budget, the specific requirements of your project, and the expertise of your electrician.

How Does Distance Affect Wire Size?

The length of the wire run is another critical factor to consider when determining what size of wire for 100 amp service is appropriate. As the distance increases, the resistance in the wire also increases, leading to a phenomenon known as voltage drop. Voltage drop occurs when the electrical current loses strength as it travels through the wire, resulting in reduced performance of your electrical devices.

Read also:Discovering Kevin Beets A Journey Through His Life And Achievements

To mitigate voltage drop, thicker wires are often required for longer runs. For example, if your 100-amp service is located far from the main panel, you might need to upgrade from a 2 AWG copper wire to a 1/0 AWG copper wire. Similarly, aluminum wires may require even larger sizes to achieve the same results. Calculating the appropriate wire size based on distance ensures that your electrical system operates efficiently and safely, regardless of the length of the circuit.

What Are the Key Factors in Choosing the Right Wire?

Selecting the correct wire size for a 100-amp service involves more than just considering the current load. Several other factors play a role in determining the ideal wire for your project. These include temperature conditions, insulation types, and the specific requirements of your installation. Understanding these factors ensures that your electrical system is both safe and efficient.

Temperature Conditions and Their Impact

Temperature is a critical consideration when selecting wire size. Wires are rated for specific temperature ranges, and exceeding these limits can lead to overheating and potential hazards. For example, if your installation is in a hot environment, such as an attic or a region with high ambient temperatures, you may need to choose a wire with a higher temperature rating or increase the wire size to compensate for the heat.

Additionally, the type of insulation used on the wire can affect its temperature tolerance. Wires with higher-grade insulation, such as THHN or XHHW, are better suited for high-temperature environments. These materials provide greater resistance to heat and abrasion, ensuring the longevity and safety of your electrical system. Always consult the manufacturer’s specifications to ensure the wire you choose is suitable for the conditions it will face.

Insulation Types and Their Role

Insulation is another key factor in wire selection. The type of insulation used determines the wire’s ability to withstand environmental conditions, such as moisture, heat, and abrasion. For a 100-amp service, common insulation types include THHN, XHHW, and UF. Each type has its own advantages and is suited for specific applications.

- THHN: This is a heat-resistant nylon-coated wire commonly used in dry environments. It’s ideal for indoor applications where moisture is not a concern.

- XHHW: This wire is designed for wet and high-temperature environments, making it a versatile choice for outdoor and underground installations.

- UF: Underground feeder wire is specifically designed for direct burial applications. It’s moisture-resistant and suitable for outdoor use.

Selecting the right insulation type ensures that your wire can withstand the conditions it will encounter, providing long-term reliability and safety.

How to Calculate Voltage Drop for 100-Amp Service?

Voltage drop is an important consideration when determining what size of wire for 100 amp service is appropriate. It occurs when the electrical current loses strength as it travels through the wire, resulting in reduced performance of your devices. To calculate voltage drop, you need to know the wire’s resistance, the current load, and the length of the circuit. The formula for voltage drop is:

Voltage Drop = (2 x Length x Current x Resistance) / 1000

For example, if you have a 100-amp service with a 100-foot wire run and a resistance of 0.194 ohms per 1,000 feet, the voltage drop would be:

Voltage Drop = (2 x 100 x 100 x 0.194) / 1000 = 3.88 volts

A voltage drop of more than 3% is generally considered unacceptable, so you may need to increase the wire size to reduce resistance and improve performance.

What Are the NEC Guidelines for 100-Amp Wiring?

The National Electrical Code (NEC) provides clear guidelines for wire sizing to ensure safety and compliance. For a 100-amp service, the NEC recommends using 2 AWG copper or 1/0 AWG aluminum wires. These sizes are designed to handle the current load while minimizing voltage drop and heat buildup. Additionally, the NEC requires that all wiring installations comply with local codes and regulations, which may impose additional requirements.

Common Mistakes to Avoid When Selecting Wire Size

Choosing the wrong wire size can have serious consequences, from electrical fires to system failures. Here are some common mistakes to avoid:

- Underestimating the current load: Always calculate the total load your system will carry to ensure the wire can handle it.

- Ignoring environmental factors: Temperature, moisture, and distance can all affect wire performance.

- Using the wrong insulation type: Ensure the insulation is suitable for the conditions it will face.

Understanding The Definition Of A Pond Vs Lake: Key Differences And Insights

Discovering Fawcett Oliver Glass: A Journey Through Art And Innovation

Understanding The Legal Age Of Consent In Russia: A Comprehensive Guide

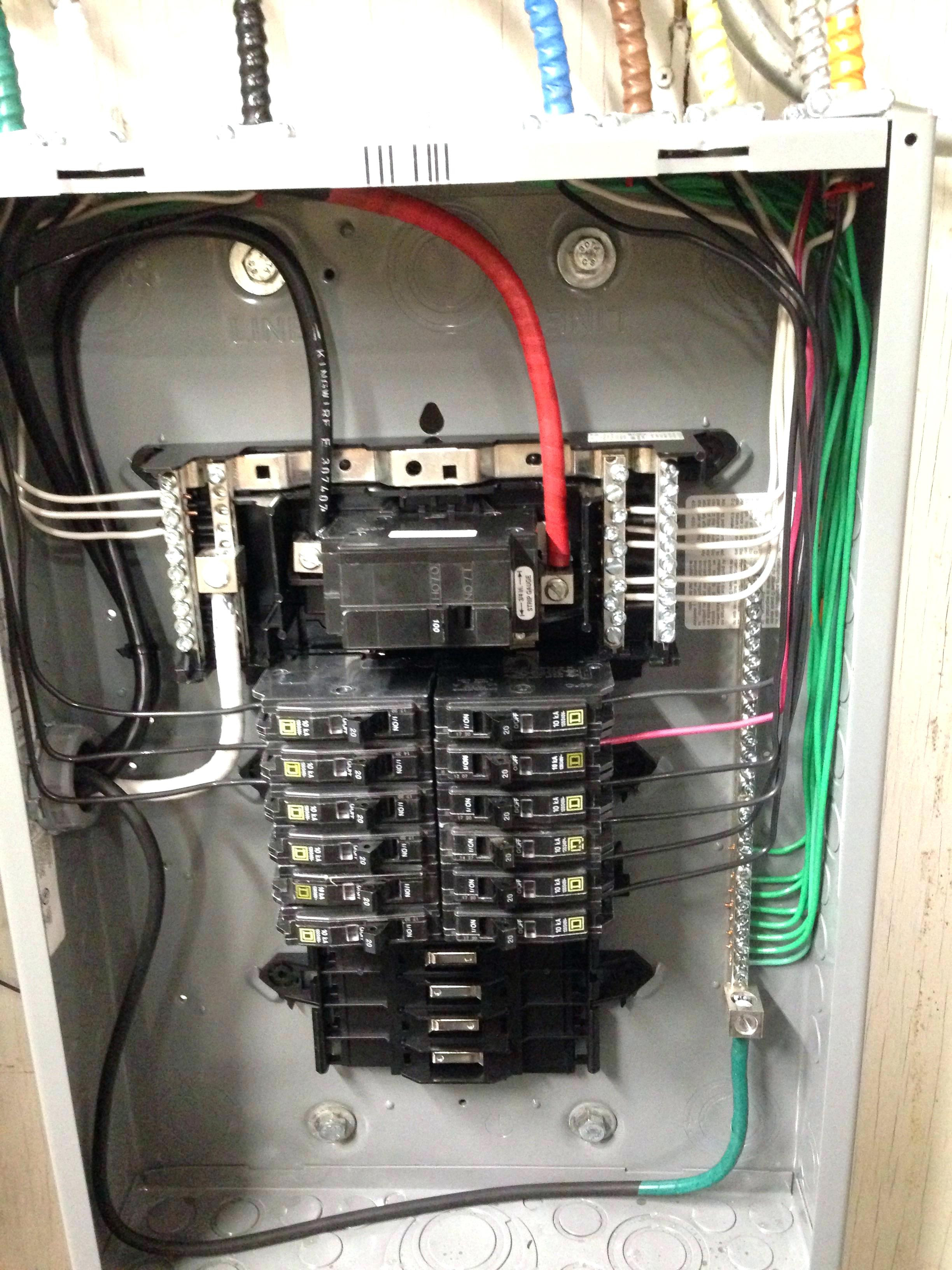

What Is the Correct Wire Size for 100Amp Service? Angi

What Size Wire 100 Amp Subpanel