What Size Wire For 100 Amp Service? A Complete Guide To Safe Wiring

When it comes to electrical systems, safety and efficiency are non-negotiable. One of the most common questions homeowners and electricians face is, "What size wire for 100 amp service?" Choosing the correct wire gauge is critical to ensure your electrical system operates safely and avoids hazards like overheating, fires, or equipment failure. A 100 amp service is standard for many homes, powering everything from appliances to HVAC systems. Understanding the wire size requirements is essential for both new installations and upgrades to existing systems.

Electrical codes, such as the National Electrical Code (NEC), provide guidelines for wire sizing, but these can sometimes feel overwhelming for those unfamiliar with electrical terminology. The wire size you need depends on several factors, including the distance from the power source, the type of wire material (copper or aluminum), and the environment where the wire will be installed. Copper wires, for instance, are more conductive and can often be smaller in diameter compared to aluminum wires for the same amperage. Properly sizing your wire ensures compliance with safety standards and maximizes the lifespan of your electrical system.

Whether you're a DIY enthusiast or consulting with a licensed electrician, understanding the nuances of wire sizing for a 100 amp service can save you time, money, and potential headaches. In this comprehensive guide, we’ll explore everything you need to know about wire sizes, materials, and installation considerations. By the end, you’ll have the confidence to make informed decisions about your electrical setup or communicate effectively with professionals.

Read also:What Are Examples A Comprehensive Guide To Understanding And Using Examples Effectively

Table of Contents

- What Size Wire for 100 Amp Service?

- Why Is Wire Size Important for 100 Amp Service?

- How Do You Choose the Right Wire Material?

- What Are the Factors Affecting Wire Size?

- How to Install Wires for 100 Amp Service?

- Common Mistakes to Avoid When Selecting Wire Size

- What Are the Local Codes and Regulations?

- FAQs About Wire Size for 100 Amp Service

What Size Wire for 100 Amp Service?

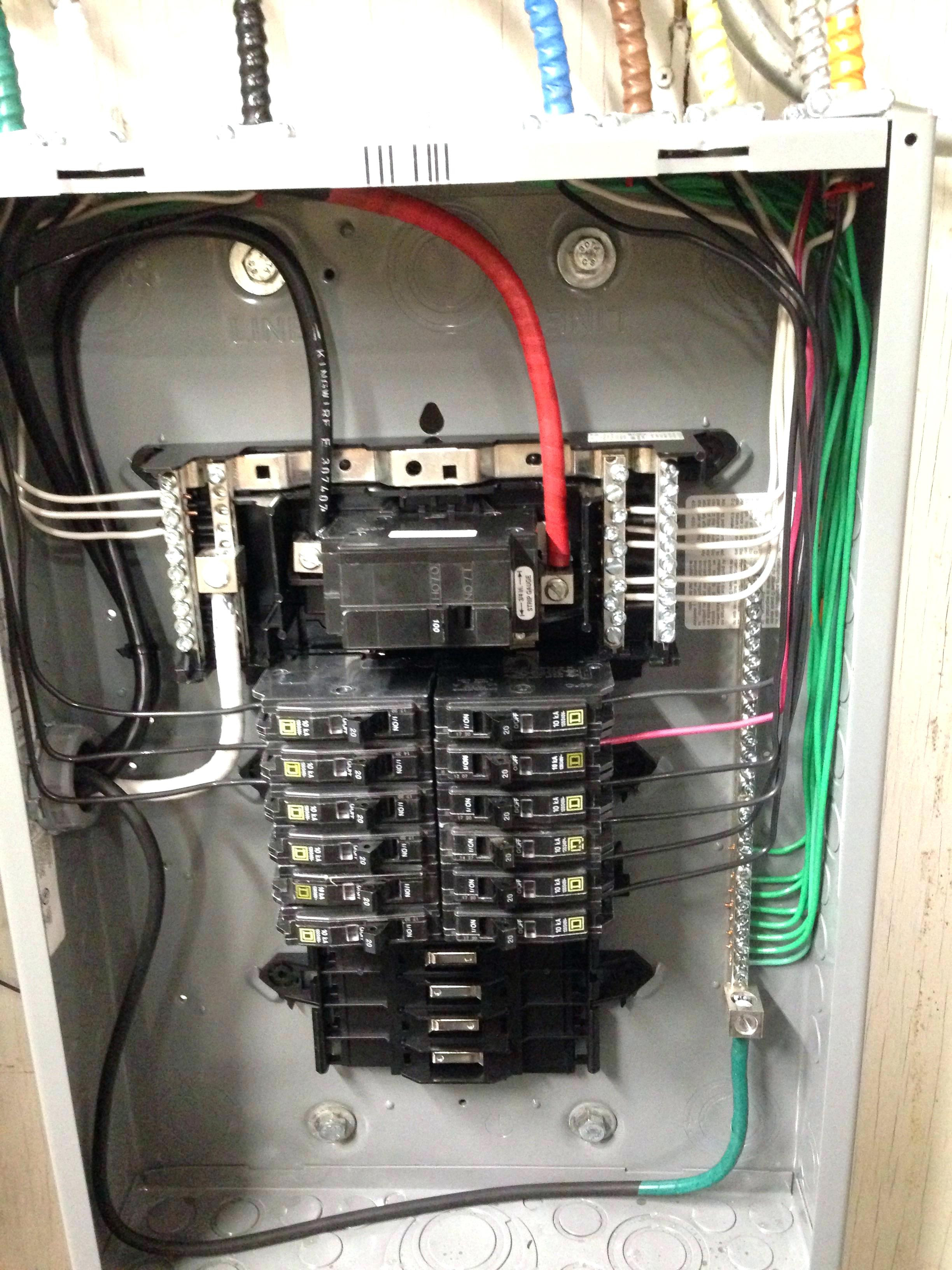

The size of the wire you need for a 100 amp service depends on various factors, including the material of the wire and the length of the run. For most residential applications, a 100 amp service typically requires a 2-gauge copper wire or a 1/0-gauge aluminum wire. These sizes are recommended because they can safely carry the current without overheating, provided the distance from the power source is within standard limits.

If your electrical panel is located far from the utility connection, you may need to increase the wire size to compensate for voltage drop. Voltage drop occurs when electrical resistance in the wire reduces the voltage available at the end of the circuit. To minimize this, larger wires are used to ensure the system remains efficient and safe. For example, a 100-foot run might require a 1-gauge copper wire instead of a 2-gauge wire to maintain optimal performance.

It's also important to note that the wire size must comply with the NEC guidelines. These guidelines specify the minimum wire gauge for specific amperage levels to prevent overheating and potential fire hazards. Always consult a professional electrician or refer to the NEC when determining the appropriate wire size for your 100 amp service.

Why Is Wire Size Important for 100 Amp Service?

Choosing the correct wire size is crucial for the safety and efficiency of your electrical system. Undersized wires can lead to overheating, which poses a significant fire risk. On the other hand, oversized wires can be unnecessarily expensive and difficult to work with. The right balance ensures your system operates safely and efficiently, meeting the demands of modern appliances and electronics.

Another reason wire size matters is voltage drop. When wires are too small for the distance they need to cover, the voltage at the end of the circuit may drop below acceptable levels. This can cause appliances to malfunction or wear out prematurely. Properly sized wires help maintain consistent voltage, ensuring your devices operate as intended.

Finally, using the correct wire size ensures compliance with local codes and regulations. Electrical inspectors will check that your wiring meets NEC standards, and failing to adhere to these guidelines can result in fines or delays in project completion. Always prioritize safety and compliance when selecting wire sizes for your 100 amp service.

Read also:Rick Moranis A Comprehensive Look At The Comedy Legends Life And Legacy

How Do You Choose the Right Wire Material?

Copper vs. Aluminum Wires

When selecting wire material for a 100 amp service, you have two primary options: copper and aluminum. Copper is the preferred choice for most residential applications due to its superior conductivity and durability. It can carry more current than aluminum for the same wire gauge, making it ideal for high-demand systems. However, copper is more expensive, which can be a limiting factor for some projects.

Aluminum wires, while less conductive, are a cost-effective alternative. They are lighter and easier to handle, making them suitable for long-distance runs or large-scale installations. However, aluminum is more prone to corrosion and requires special connectors to prevent oxidation. It's essential to weigh the pros and cons of each material based on your specific needs and budget.

Cost and Performance Comparison

Let’s break down the cost and performance differences between copper and aluminum wires:

- Cost: Aluminum wires are typically 30-50% cheaper than copper wires, making them an attractive option for budget-conscious projects.

- Performance: Copper wires offer better conductivity and are less prone to expansion and contraction, which can lead to loose connections in aluminum wires.

- Durability: Copper is more resistant to corrosion and wear, ensuring a longer lifespan for your electrical system.

- Installation: Aluminum wires require anti-oxidant compounds and specialized connectors to prevent corrosion and ensure safe connections.

Ultimately, the choice between copper and aluminum depends on your budget, the specific requirements of your project, and local regulations. Consulting with a licensed electrician can help you make the best decision for your needs.

What Are the Factors Affecting Wire Size?

Distance and Voltage Drop

The distance between the power source and the electrical panel plays a significant role in determining the appropriate wire size. Longer runs require larger wires to compensate for voltage drop, which occurs when electrical resistance reduces the voltage available at the end of the circuit. For a 100 amp service, the NEC recommends limiting voltage drop to 3% or less to ensure optimal performance.

To calculate voltage drop, you can use the following formula:

Voltage Drop = (2 x Length x Current x Resistance) / 1000

Where:

- Length: The distance from the power source to the panel in feet.

- Current: The amperage of the circuit (100 amps in this case).

- Resistance: The resistance of the wire per 1,000 feet, which varies by gauge and material.

By using this formula, you can determine whether you need to upgrade to a larger wire size to maintain acceptable voltage levels.

Environmental Conditions

Environmental factors such as temperature, moisture, and exposure to sunlight can also impact wire size requirements. For example, wires installed in hot environments may need to be larger to account for increased resistance. Similarly, wires exposed to moisture or direct sunlight may require additional insulation or protective coatings to prevent damage.

It's essential to consider these factors when planning your installation. For outdoor applications, use wires rated for wet or damp conditions, such as THWN or UF cables. For indoor installations, ensure the wires are protected from physical damage and excessive heat.

How to Install Wires for 100 Amp Service?

Installing wires for a 100 amp service requires careful planning and adherence to safety guidelines. Begin by turning off the main power supply to prevent electrical hazards. Next, measure the distance between the power source and the electrical panel to determine the appropriate wire size. Use a conduit to protect the wires from physical damage and ensure they are securely fastened to prevent movement.

When connecting the wires to the electrical panel, use the appropriate connectors and terminals. For aluminum wires, apply anti-oxidant compounds to prevent corrosion and ensure a secure connection. Double-check all connections to ensure they are tight and free of defects. Finally, test the system to verify that it operates correctly and meets safety standards.

Common Mistakes to Avoid When Selecting Wire Size

Selecting the wrong wire size is a common mistake that can lead to serious consequences. One frequent error is underestimating the distance from the power source, resulting in excessive voltage drop. Another mistake is using aluminum wires without the proper connectors, which can lead to loose connections and potential fire hazards.

To avoid these pitfalls, always consult the NEC guidelines and work with a licensed electrician. Double-check your calculations and ensure all materials meet the required specifications. Taking these precautions will help you avoid costly mistakes and ensure your electrical system operates safely and efficiently.

What Are the Local Codes and Regulations?

Local codes and regulations play a crucial role in determining wire size requirements for a 100 amp service. While the NEC provides a baseline for electrical safety, local jurisdictions may have additional requirements. For example, some areas may mandate specific wire gauges for outdoor installations or require permits for new electrical work.

Always check with your local building department before beginning any electrical project. They can provide guidance on the necessary permits and inspections to ensure your installation complies with all applicable codes. Working with a licensed electrician who is familiar with local regulations can also help streamline the process and ensure compliance.

FAQs About Wire Size for 100 Amp Service

What Size Wire for 100 Amp Service is Recommended?

For a 100 amp service, a 2-gauge copper wire or a 1/0-gauge aluminum wire is typically recommended. These sizes ensure safe and efficient operation within standard distance limits.

Can I Use Aluminum Wire for a 100 Amp Service?

Yes, aluminum wire can be used for a 100 amp service, but it requires special connectors and anti-oxidant compounds to prevent corrosion and ensure secure connections.

How Do I Calculate Voltage Drop for a 100 Amp Service?

To calculate voltage drop, use the formula: Voltage Drop = (2 x Length x Current x Resistance) / 1000. Ensure the voltage drop is within 3% of the total voltage to maintain optimal performance.

Conclusion

Selecting the correct wire size for a 100 amp service is essential for safety, efficiency, and compliance with local codes. By understanding the factors that influence wire size, such as material, distance, and environmental conditions, you can make informed decisions about your electrical system. Whether you're a DIY enthusiast or working with a professional electrician, this guide provides the knowledge you need to ensure a successful installation.

For further reading, you can explore the

Discovering The Hidden Beauty Of Heptagons In Nature

Exploring Rutgers ZOM: Everything You Need To Know About This Innovative Concept

Exploring Ioan Gruffudd's Net Worth: A Glimpse Into The Welsh Actor’s Success

What Size Wire 100 Amp Subpanel

How To Wire 200 Amp Service Disconnect