What Size Wire For 100 Amp Service: A Comprehensive Guide

Choosing the correct wire size for a 100 amp service is crucial for ensuring safety and efficiency in your electrical system. Whether you're upgrading your home's electrical panel or installing a subpanel in your workshop, understanding the requirements for 100 amp wiring is essential. Using the wrong size wire can lead to overheating, electrical fires, or system failures, which is why it's vital to get it right. This guide will walk you through everything you need to know about selecting the appropriate wire size for 100 amp service, ensuring compliance with electrical codes and maximizing performance.

When dealing with electrical systems, there are several factors to consider, such as the distance the wire needs to travel, the material of the wire (copper or aluminum), and the specific application. For instance, copper wires generally have better conductivity than aluminum, which means they can carry the same current with a smaller gauge. However, aluminum is often more cost-effective for longer runs. Understanding these nuances will help you make informed decisions about your wiring needs. This article will also explore the National Electrical Code (NEC) guidelines, which dictate the minimum wire size for 100 amp services to ensure safety and reliability.

In addition to wire size, we'll delve into other considerations like voltage drop, insulation types, and the importance of professional installation. Voltage drop becomes especially important for long wire runs, as excessive drop can reduce the efficiency of your electrical system. Proper insulation is also critical to protect the wire from environmental factors and ensure longevity. By the end of this guide, you'll have a thorough understanding of what size wire for 100 amp service is appropriate for your specific needs, empowering you to make the best choices for your home or business.

Read also:Who Is Patricia Brights Husband A Deep Dive Into Her Personal Life And Influence

Table of Contents

- What is 100 Amp Service and Why Does Wire Size Matter?

- How to Determine the Right Wire Size for 100 Amp Service?

- Copper vs. Aluminum: Which Wire Material is Best for 100 Amp Service?

- What Factors Affect Wire Size Selection for 100 Amp Service?

- Why is Voltage Drop Important When Choosing Wire for 100 Amp Service?

- What Are the NEC Guidelines for 100 Amp Wire Size?

- Installation Tips for 100 Amp Wiring: What You Need to Know

- What Are the Common Mistakes to Avoid When Wiring for 100 Amp Service?

What is 100 Amp Service and Why Does Wire Size Matter?

A 100 amp service refers to the capacity of your electrical panel to deliver electricity to your home or business. This service size is common in many residential properties, especially older homes, and is sufficient for powering standard appliances, lighting, and HVAC systems. However, as electrical demands increase with modern technology, understanding the role of wire size becomes even more critical. The wire size for a 100 amp service must be able to handle the current load without overheating, which could pose serious safety risks.

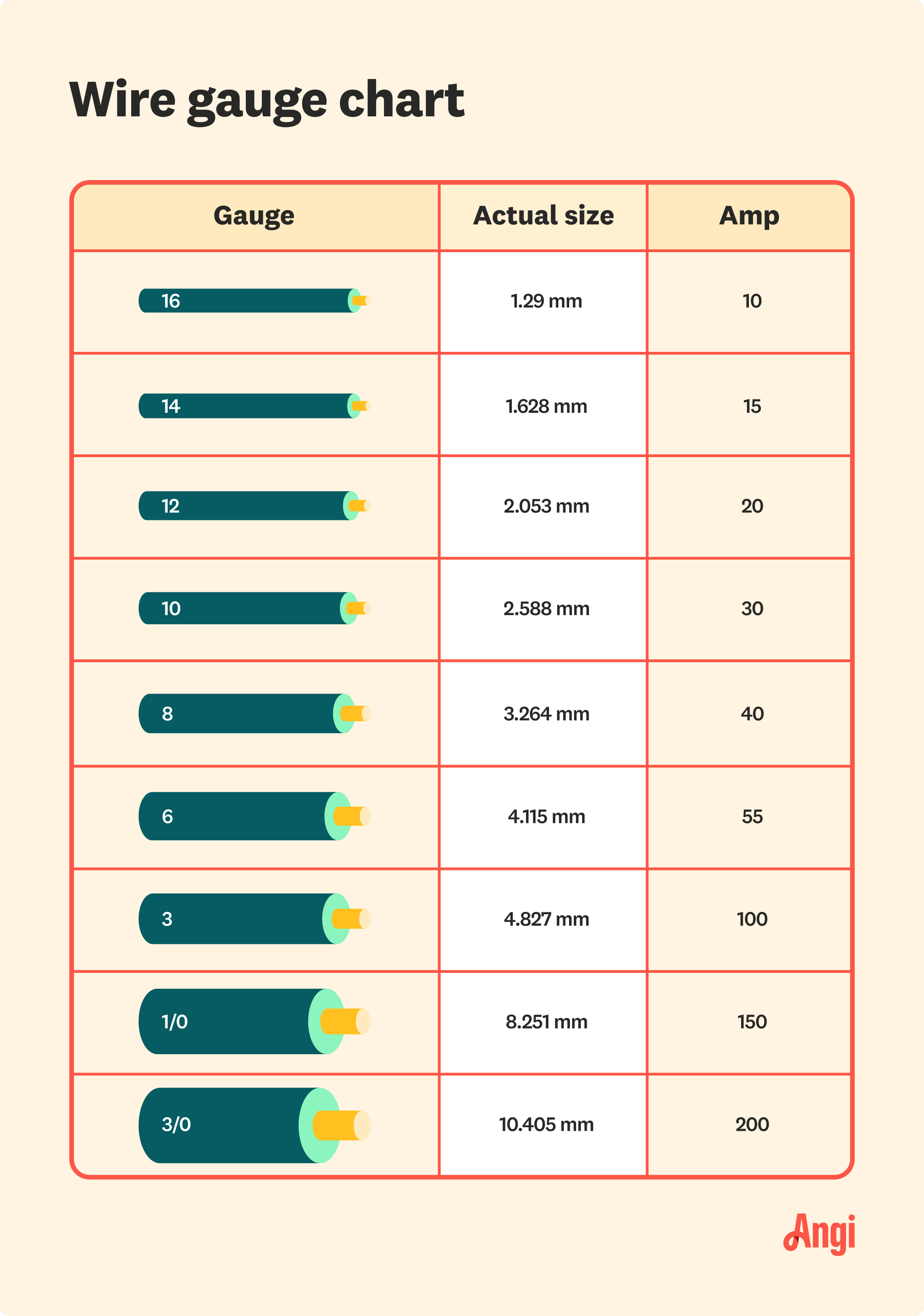

The wire size is measured in American Wire Gauge (AWG), and the correct gauge ensures that the wire can safely carry the electrical load. For a 100 amp service, the NEC typically recommends using a 3 AWG copper wire or a 1 AWG aluminum wire. These sizes are designed to minimize resistance and prevent overheating, which can occur if the wire is too small for the current it needs to carry. Using the wrong wire size not only jeopardizes safety but can also lead to inefficient energy usage and increased utility bills.

Moreover, wire size directly impacts the performance of your electrical system. If the wire is too thin, it can cause voltage drop, which reduces the efficiency of your appliances and electronics. On the other hand, using a wire that's too large for the application can be unnecessarily expensive and cumbersome to install. Therefore, striking the right balance is essential for both safety and cost-effectiveness. This section will further explore how to determine the appropriate wire size for your specific needs.

How to Determine the Right Wire Size for 100 Amp Service?

Choosing the correct wire size for a 100 amp service involves several considerations, including the type of wire, the length of the run, and the specific application. To start, it's important to understand the basic principles of electrical current and resistance. The wire must be able to carry the current load without excessive resistance, which can cause overheating and energy loss. For a 100 amp service, the wire size is typically determined by the material (copper or aluminum) and the distance the wire needs to travel.

For short runs, a 3 AWG copper wire is usually sufficient for a 100 amp service. However, for longer distances, you may need to increase the wire size to compensate for voltage drop. Voltage drop occurs when the resistance in the wire causes a reduction in voltage as electricity travels from the source to the load. To minimize this, you can use a larger wire gauge or choose a material with better conductivity, like copper. Here’s a quick guide to help you determine the appropriate wire size:

- Short Runs (up to 50 feet): 3 AWG copper or 1 AWG aluminum.

- Medium Runs (50-100 feet): 2 AWG copper or 1/0 AWG aluminum.

- Long Runs (over 100 feet): 1 AWG copper or 2/0 AWG aluminum.

Additionally, it's important to consult the NEC guidelines, which provide specific recommendations for wire size based on the application. These guidelines ensure that your wiring meets safety standards and performs efficiently under various conditions. By understanding these factors, you can confidently select the right wire size for your 100 amp service.

Read also:Dawn Wells Measurements A Complete Guide To Her Life And Career

Copper vs. Aluminum: Which Wire Material is Best for 100 Amp Service?

When it comes to choosing between copper and aluminum wires for a 100 amp service, both materials have their pros and cons. Copper is widely regarded as the superior choice due to its excellent conductivity, durability, and resistance to corrosion. It can carry the same current as aluminum with a smaller gauge, making it ideal for tight spaces. However, copper is also more expensive, which can be a significant factor for larger projects or longer wire runs.

Aluminum, on the other hand, is more cost-effective and lighter, making it easier to handle during installation. However, it has higher resistance and is more prone to oxidation, which can lead to overheating if not properly maintained. For a 100 amp service, aluminum wire typically needs to be one or two sizes larger than copper to achieve the same performance. For example, a 1 AWG aluminum wire is roughly equivalent to a 3 AWG copper wire in terms of current-carrying capacity.

Ultimately, the choice between copper and aluminum depends on your budget, the specific application, and the length of the wire run. If you're working on a tight budget or need to cover long distances, aluminum may be the better option. However, for shorter runs or applications where performance and longevity are critical, copper is the preferred choice. Consulting with a licensed electrician can help you make the best decision based on your unique circumstances.

Why Choose Copper Over Aluminum for 100 Amp Service?

Copper's superior conductivity and durability make it the preferred choice for many electrical applications, including 100 amp services. Its ability to carry higher currents with smaller gauges reduces the risk of overheating and voltage drop. Additionally, copper is less prone to corrosion, ensuring a longer lifespan for your electrical system. These advantages make it a worthwhile investment, especially for critical applications where safety and performance are paramount.

When is Aluminum Wire a Better Option for 100 Amp Service?

Aluminum wire is often chosen for its cost-effectiveness and lighter weight, making it ideal for long runs or large-scale projects. While it requires larger gauges to match the performance of copper, its affordability can offset the additional material costs. However, proper installation and maintenance are crucial to prevent issues like oxidation and overheating. For applications where budget constraints are a primary concern, aluminum wire can be a practical solution.

What Factors Affect Wire Size Selection for 100 Amp Service?

Several factors influence the selection of wire size for a 100 amp service, including the length of the run, the material of the wire, and the specific application. Each of these factors plays a critical role in ensuring the safety and efficiency of your electrical system. For instance, longer wire runs require larger gauges to compensate for voltage drop, while shorter runs can use smaller gauges without compromising performance.

The material of the wire is another key consideration. Copper wires are more conductive and durable but come at a higher cost. Aluminum wires, while less expensive, require larger gauges to achieve the same current-carrying capacity. Additionally, the type of insulation used on the wire can impact its performance. For example, wires with thicker insulation are better suited for outdoor or underground applications, as they provide additional protection against moisture and environmental factors.

Finally, the specific application of the wire must be taken into account. For instance, wires used in subpanels or detached structures may have different requirements than those used in the main service panel. Understanding these factors will help you make informed decisions about wire size and ensure compliance with electrical codes and safety standards.

How Does Wire Length Affect Voltage Drop in 100 Amp Service?

Wire length is a critical factor in determining voltage drop, which can impact the efficiency of your electrical system. Longer wire runs increase resistance, leading to a greater voltage drop as electricity travels from the source to the load. To minimize this, you can use larger wire gauges or choose materials with better conductivity, such as copper. Properly accounting for wire length ensures optimal performance and reduces the risk of energy loss.

What Role Does Insulation Play in Wire Selection for 100 Amp Service?

Insulation is essential for protecting wires from environmental factors and ensuring their longevity. Different types of insulation are designed for specific applications, such as indoor, outdoor, or underground use. For a 100 amp service, choosing the right insulation can prevent issues like overheating, moisture damage, and electrical faults. Understanding the role of insulation helps you select the most suitable wire for your needs.

Why is Voltage Drop Important When Choosing Wire for 100 Amp Service?

Voltage drop is a critical consideration when selecting wire for a 100 amp service, as it directly impacts the efficiency and performance of your electrical system. Excessive voltage drop can cause appliances and electronics to operate below their optimal capacity, leading to increased energy consumption and reduced lifespan. To minimize voltage drop, it's essential to choose the correct wire size based on the length of the run and the material of the wire.

For short runs, voltage drop is generally not a significant concern, and standard wire sizes can be used. However, for longer runs, especially those exceeding 100 feet, it's important to increase the wire gauge to compensate for the additional resistance. For example, a 2 AWG copper wire or a 1/0 AWG aluminum wire is typically recommended for runs between 50 and 100 feet. These larger gauges help maintain consistent voltage levels and ensure efficient energy delivery.

In addition to wire size, using materials with better conductivity, such as copper, can also help reduce voltage drop. Proper installation techniques, such as minimizing bends and avoiding tight spaces, can further improve performance. By understanding the importance of voltage drop and how to mitigate it, you can ensure that your 100 amp service operates safely and efficiently.

What Are the NEC Guidelines for 100 Amp Wire Size?

The National Electrical Code (NEC) provides specific guidelines for wire size in 100 amp services to ensure safety and compliance. According to the NEC, the minimum wire size for a 100 amp service is typically 3 AWG copper or 1 AWG aluminum. These recommendations are based on the current-carrying capacity of the wire and its ability to handle the electrical load without overheating.

In addition to wire size, the NEC also specifies requirements for insulation, grounding, and protection against environmental factors. For example, wires used in wet or damp locations must have moisture-resistant insulation, such as THWN or XHHW. Proper grounding is also essential to prevent electrical faults and ensure the safety of your system. By adhering to these guidelines, you can ensure that your wiring meets industry standards and performs reliably under various conditions.

It's important to note that local building codes may have additional requirements beyond the NEC guidelines. Therefore, it's always a good idea to consult with a licensed electrician or local authority to ensure compliance with all applicable regulations. By following these guidelines, you can create

Who Is Piastri Father? Unveiling The Man Behind Oscar Piastri's Success

Does Homeowners Insurance Cover Sewer Line Replacement? A Complete Guide

Discover The Best Spots For Tattoos: A Comprehensive Guide

What Is the Correct Wire Size for 100Amp Service? Angi

Silicone wire size vs withstand current (wire amp chart) esk8.news