What You Need To Know About 100 Amp Panel Wire Size: A Comprehensive Guide

Whether you're upgrading your home's electrical panel or installing a new one, understanding the appropriate wire gauge ensures that your system operates without overheating or risking electrical fires. A 100 amp panel is a common choice for many households, as it provides sufficient power to meet the needs of modern appliances and devices. However, the wire size you choose must match the amperage rating of the panel to ensure optimal performance and compliance with electrical codes. Selecting the right wire size involves more than just matching numbers; it requires understanding factors like the distance between the panel and the power source, the type of wire material (copper or aluminum), and the specific demands of your electrical system. Copper wires, for instance, are more conductive and can carry the same current as aluminum wires with a smaller gauge. This makes copper a popular choice despite its higher cost. On the other hand, aluminum wires are lighter and less expensive, but they require a larger gauge to handle the same load. These considerations are vital for homeowners, electricians, and DIY enthusiasts alike, as they directly impact the safety and reliability of your electrical setup. In this guide, we’ll explore everything you need to know about 100 amp panel wire size, from the basics of wire gauges to advanced considerations like voltage drop and material selection. By the end of this article, you’ll have a clear understanding of how to determine the correct wire size for your 100 amp panel and why it’s essential for maintaining a safe and efficient electrical system. Whether you’re a homeowner planning a renovation or a professional electrician looking for a refresher, this comprehensive resource will equip you with the knowledge you need to make informed decisions.

Table of Contents

- Why Does 100 Amp Panel Wire Size Matter?

- What Are the Common Wire Gauges for a 100 Amp Panel?

- How Do You Calculate Voltage Drop for 100 Amp Wire Size?

- What Material Should You Choose for 100 Amp Panel Wires?

- How Does Distance Affect 100 Amp Panel Wire Size?

- What Are the Safety Standards for 100 Amp Wire Installation?

- What Are the Common Mistakes to Avoid?

- FAQs About 100 Amp Panel Wire Size

Why Does 100 Amp Panel Wire Size Matter?

Choosing the correct wire size for a 100 amp panel is not just a matter of convenience—it’s a critical safety requirement. The wire gauge determines how much current can safely pass through the wire without overheating. If the wire is too small for the amperage, it can overheat, leading to insulation damage, electrical fires, or even complete system failure. Conversely, using a wire that’s too large may be unnecessarily expensive and cumbersome to install.

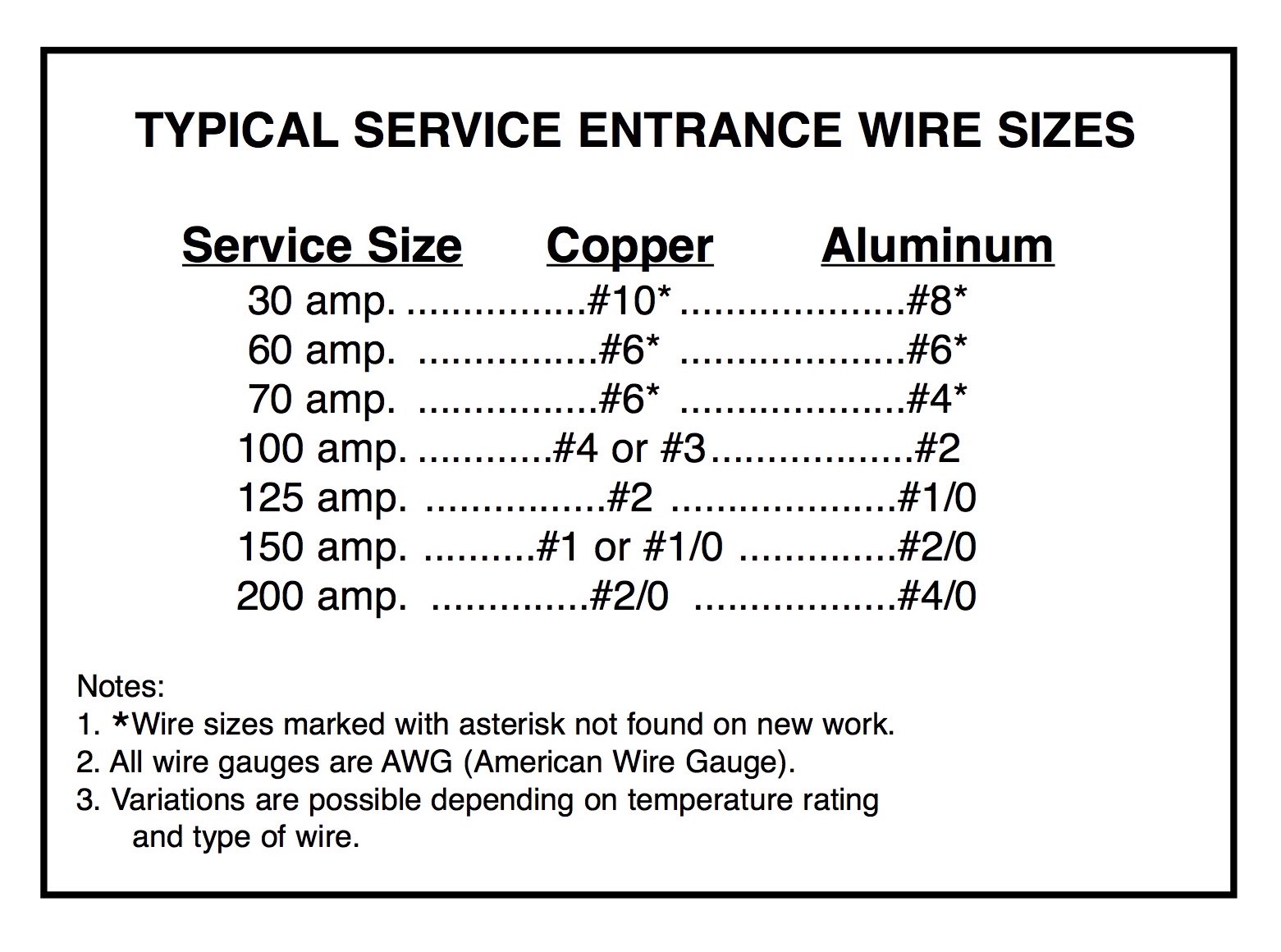

Electrical codes, such as the National Electrical Code (NEC), provide guidelines for wire sizing to ensure safety and compliance. These codes specify minimum wire gauges for different amperage ratings, taking into account factors like material type and circuit length. For a 100 amp panel, the NEC typically recommends using a wire gauge of 3 AWG for copper or 1 AWG for aluminum. However, these recommendations can vary depending on the specific circumstances of your installation.

Read also:Discover The Magic Of Richard Dreyfuss Movies A Journey Through Time

Why Is Compliance with Electrical Codes Important?

Compliance with electrical codes is not optional—it’s a legal requirement in most jurisdictions. These codes are designed to protect both property and people from the dangers of electrical hazards. Failure to adhere to these standards can result in fines, insurance claim denials, or even legal liability in the event of an accident. Additionally, non-compliant installations may void warranties or lead to issues when selling your property.

What Happens If You Ignore Wire Size Recommendations?

Ignoring wire size recommendations can have severe consequences. Overloaded wires can overheat, melt insulation, and cause electrical fires. Even if a fire doesn’t occur, overheating can degrade the wire over time, leading to intermittent power issues or complete system failure. Furthermore, improper wire sizing can cause voltage drop, which reduces the efficiency of your appliances and may damage sensitive electronics.

What Are the Common Wire Gauges for a 100 Amp Panel?

When selecting a wire gauge for a 100 amp panel, the most common options are 3 AWG for copper and 1 AWG for aluminum. These gauges are recommended because they can safely carry the current required by a 100 amp service without overheating. However, it’s important to note that these are general guidelines, and specific installations may require adjustments based on factors like distance and ambient temperature.

Why Does Material Choice Affect Wire Gauge?

The material of the wire—copper or aluminum—plays a significant role in determining the appropriate gauge. Copper is more conductive than aluminum, meaning it can carry the same current with a smaller wire size. For example, a 3 AWG copper wire can handle the same load as a 1 AWG aluminum wire. This makes copper a preferred choice for many installations, despite its higher cost.

What Are the Pros and Cons of Copper vs. Aluminum Wires?

- Copper Wires: Highly conductive, durable, and resistant to corrosion, but more expensive.

- Aluminum Wires: Lightweight, cost-effective, and easier to work with, but require larger gauges and are more prone to corrosion.

How Do You Calculate Voltage Drop for 100 Amp Wire Size?

Voltage drop occurs when the resistance in a wire causes a reduction in voltage as electricity travels from the source to the load. For a 100 amp panel, excessive voltage drop can lead to inefficient appliance performance and potential damage to sensitive electronics. Calculating voltage drop involves understanding the wire’s resistance, the current flowing through it, and the length of the circuit.

The formula for voltage drop is:

Read also:Unblocked Games Your Ultimate Guide To Fun And Learning

Voltage Drop = (2 × Length × Current × Resistance) / 1000

Where:

- Length is the distance from the power source to the panel in feet.

- Current is the amperage (100 amps in this case).

- Resistance depends on the wire gauge and material.

Why Is Voltage Drop Important for 100 Amp Panels?

Voltage drop is especially important for 100 amp panels because these systems often supply power to multiple high-demand appliances. A significant voltage drop can cause appliances to underperform or fail, leading to frustration and potential damage. The NEC recommends keeping voltage drop below 3% for branch circuits and 5% for feeders to ensure optimal performance.

How Can You Minimize Voltage Drop?

To minimize voltage drop, you can:

- Use a larger wire gauge to reduce resistance.

- Shorten the distance between the power source and the panel.

- Choose copper over aluminum for better conductivity.

What Material Should You Choose for 100 Amp Panel Wires?

The choice between copper and aluminum wires is one of the most important decisions when installing a 100 amp panel. Each material has its advantages and disadvantages, and the best choice depends on your budget, installation requirements, and long-term goals.

Why Is Copper Often Preferred for 100 Amp Panels?

Copper is the gold standard for electrical wiring due to its superior conductivity, durability, and resistance to corrosion. It’s particularly well-suited for high-amperage applications like 100 amp panels because it can carry more current with a smaller gauge. Additionally, copper wires are less prone to expansion and contraction, which reduces the risk of loose connections over time.

When Should You Consider Aluminum Wires?

Aluminum wires are a cost-effective alternative to copper, especially for long-distance runs where the weight of the wire is a concern. However, aluminum requires special connectors and anti-oxidant compounds to prevent corrosion and ensure secure connections. It’s also more prone to expansion and contraction, which can lead to loose connections if not properly installed.

How Does Distance Affect 100 Amp Panel Wire Size?

The distance between the power source and the 100 amp panel is a critical factor in determining the appropriate wire size. Longer distances increase resistance, which can lead to voltage drop and reduced efficiency. To compensate, you may need to use a larger wire gauge to ensure the system operates safely and effectively.

Why Is Distance an Important Consideration?

For every foot of wire, there is a small amount of resistance that can add up over long distances. This resistance causes voltage drop, which can impact the performance of your electrical system. For example, a 100-foot run of 3 AWG copper wire may experience a negligible voltage drop, while a 200-foot run of the same wire could require upgrading to 2 AWG to maintain efficiency.

How Can You Determine the Right Wire Size for Long Distances?

To determine the correct wire size for long distances, you can use voltage drop calculators or consult with a licensed electrician. These tools take into account the wire material, gauge, and circuit length to provide a recommendation that ensures optimal performance and safety.

What Are the Safety Standards for 100 Amp Wire Installation?

Installing a 100 amp panel and its associated wiring requires adherence to strict safety standards. These standards are designed to protect both the installer and the end user from electrical hazards. Key considerations include proper grounding, secure connections, and compliance with local electrical codes.

Why Is Proper Grounding Essential?

Grounding is a critical safety measure that protects against electrical shocks and fires. A properly grounded 100 amp panel ensures that any excess current is safely directed into the earth, preventing damage to appliances and reducing the risk of electrocution.

What Are the Common Safety Mistakes to Avoid?

- Using undersized wires that can overheat.

- Failing to secure connections properly.

- Ignoring local electrical codes and regulations.

What Are the Common Mistakes to Avoid?

Even experienced electricians can make mistakes when installing a 100 amp panel. These errors can compromise the safety and efficiency of your electrical system. Below are some common pitfalls to watch out for:

- Using Incorrect Wire Gauge: Always verify the wire size against the amperage rating of the panel.

- Ignoring Voltage Drop: Failing to account for voltage drop can lead to inefficient performance.

- Poor Connections: Loose or corroded connections can cause overheating and electrical fires.

Why Is Professional Installation Recommended?

While DIY installations can save money, professional electricians bring expertise and experience that ensure the job is done safely and correctly. They can also help you navigate complex electrical codes and avoid costly mistakes.

FAQs About 100 Amp Panel Wire Size

What Is the Minimum Wire Size for a 100 Amp Panel?

The minimum wire size for a 100 amp panel is typically 3 AWG for copper or 1 AWG for aluminum, as per the NEC guidelines.

Can I Use a Larger Wire Gauge Than Recommended?

Yes,

Why Vanillagift.comm Is Your Ultimate Gifting Destination

Understanding AP Top 25 Rankings Criteria: A Comprehensive Guide

What’s The Difference Between A Pond And A Lake? A Comprehensive Guide

What Size Ground Wire For 100 Amp Sub Panel

What Size Ground Wire For 100 Amp Sub Panel