Choosing The Right Wire Gauge For 100 Amp: A Complete Guide

When it comes to electrical systems, safety and efficiency are paramount, and selecting the correct wire gauge for 100 amp circuits is a critical decision. The wire gauge determines the amount of current a wire can safely carry without overheating or causing electrical hazards. Whether you’re wiring a new home, upgrading an existing electrical panel, or installing heavy-duty appliances, understanding the appropriate wire gauge is essential for ensuring long-term reliability and compliance with electrical codes. Using an incorrect wire gauge can lead to overheating, electrical fires, or system failures, making it vital to get it right the first time. This guide will walk you through everything you need to know about wire gauge for 100 amp circuits, from basic principles to advanced considerations.

Electrical systems rely on wires to transmit power from the source to the load, and the size of the wire plays a crucial role in determining its capacity. The American Wire Gauge (AWG) system is the standard used to measure wire sizes, and each gauge corresponds to a specific diameter and current-carrying capacity. For 100 amp circuits, the wire gauge must be carefully chosen based on factors like the length of the wire run, the material of the wire (copper or aluminum), and the ambient temperature. Understanding these factors will help you make an informed decision and avoid costly mistakes.

In addition to safety, selecting the right wire gauge for 100 amp circuits can also impact the performance of your electrical system. Undersized wires can lead to voltage drops, which may cause appliances to underperform or malfunction. On the other hand, oversized wires can be unnecessarily expensive and difficult to work with. By the end of this article, you’ll have a comprehensive understanding of wire gauge for 100 amp circuits, empowering you to make the best choice for your specific needs.

Read also:Who Is Patricia Brights Husband A Deep Dive Into Her Personal Life And Influence

- What Is Wire Gauge and Why Does It Matter?

- How to Choose the Right Wire Gauge for 100 Amp?

- What Are the Common Materials Used for Wire Gauge?

- Factors Affecting Wire Gauge Selection for 100 Amp

- Why Is Copper Preferred Over Aluminum for 100 Amp Wires?

- How to Calculate Voltage Drop for 100 Amp Circuits?

- What Are the National Electrical Code Requirements?

- Conclusion and FAQs

What Is Wire Gauge and Why Does It Matter?

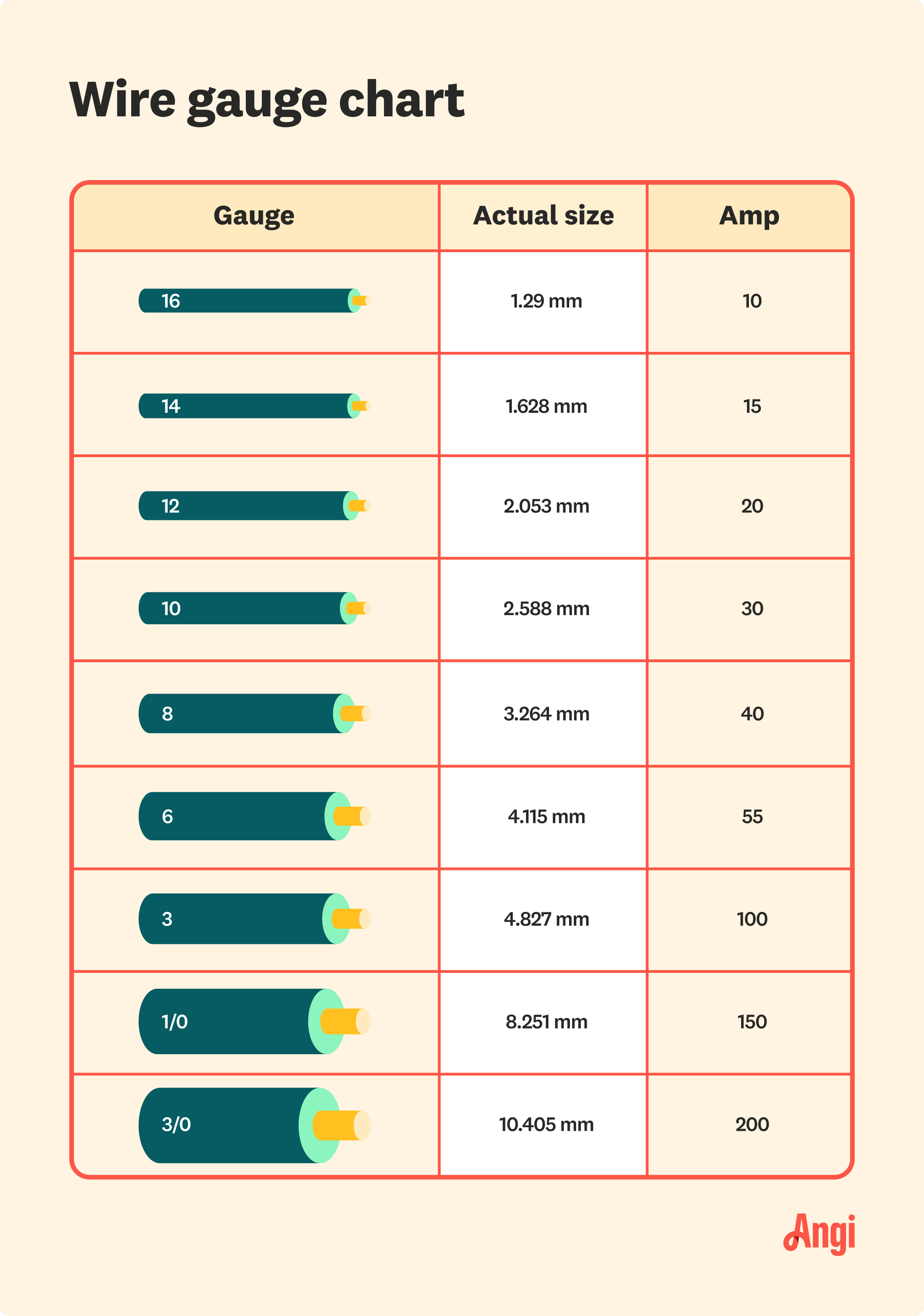

Wire gauge refers to the physical size of the wire, which is measured using the American Wire Gauge (AWG) system. The AWG scale is inversely related to the diameter of the wire, meaning that a lower gauge number corresponds to a thicker wire. For example, a 2 AWG wire is thicker and can carry more current than a 10 AWG wire. The gauge of a wire directly impacts its ability to safely carry electrical current without overheating.

Choosing the correct wire gauge is crucial for several reasons. First and foremost, it ensures the safety of your electrical system. Wires that are too thin for the current they carry can overheat, melt their insulation, and potentially cause electrical fires. Secondly, the right wire gauge ensures optimal performance. For instance, in a 100 amp circuit, using the appropriate wire gauge minimizes voltage drop, which is the reduction in voltage as electricity travels through the wire. Voltage drop can lead to inefficient operation of appliances and equipment, causing them to work harder and consume more energy.

Why Is Wire Gauge Critical for Electrical Systems?

Electrical systems are designed to operate within specific parameters, and wire gauge plays a key role in maintaining these parameters. If the wire gauge is too small, the resistance in the wire increases, leading to excessive heat generation. This not only poses a safety risk but also reduces the lifespan of the wire and connected devices. On the other hand, using a wire gauge that is too large can be unnecessarily costly and cumbersome, especially for shorter runs.

How Does Wire Gauge Relate to Current Capacity?

The current-carrying capacity of a wire, also known as its ampacity, is directly tied to its gauge. For example, a 2 AWG copper wire is typically rated for 100 amps, making it suitable for most 100 amp circuits. However, this rating can vary based on factors like the wire's insulation type and the ambient temperature. Understanding these relationships is essential for selecting the right wire gauge for 100 amp applications.

How to Choose the Right Wire Gauge for 100 Amp?

Selecting the correct wire gauge for 100 amp circuits involves considering several key factors. The most important of these is the length of the wire run. Longer runs require thicker wires to compensate for voltage drop, which occurs as electricity travels through the wire. For example, a 100-foot run may require a 1/0 AWG wire, while a 50-foot run might only need a 2 AWG wire. This is because longer wires have higher resistance, which leads to greater voltage drop.

Another critical factor is the material of the wire. Copper and aluminum are the two most common materials used for electrical wiring. Copper is more conductive than aluminum, meaning it can carry the same amount of current with a smaller diameter. As a result, copper wires are often preferred for 100 amp circuits, especially in residential applications. However, aluminum wires are lighter and less expensive, making them a popular choice for large-scale commercial installations.

Read also:Who Is Lakiha Spicer Discover The Inspiring Story Of A Rising Star

What Are the Common Materials Used for Wire Gauge?

Copper and aluminum are the two primary materials used for electrical wires, each with its own advantages and disadvantages. Copper is highly conductive, corrosion-resistant, and durable, making it the preferred choice for most residential and commercial applications. It is also easier to work with due to its flexibility and ability to bend without breaking. However, copper is more expensive than aluminum, which can be a consideration for large projects.

Aluminum, on the other hand, is lighter and more cost-effective, but it is less conductive than copper. This means that aluminum wires need to be thicker to carry the same amount of current as copper wires. Additionally, aluminum is more prone to corrosion and requires special connectors to prevent oxidation. Despite these drawbacks, aluminum is often used in industrial settings where cost and weight are significant factors.

Factors Affecting Wire Gauge Selection for 100 Amp

Several factors influence the selection of the appropriate wire gauge for 100 amp circuits. These include the length of the wire run, the material of the wire, the ambient temperature, and the type of insulation used. Each of these factors must be carefully considered to ensure the wire can safely and efficiently carry the required current.

For example, the ambient temperature can affect the ampacity of a wire. Wires installed in hot environments, such as attics or industrial settings, may need to be upsized to account for the increased temperature. Similarly, the type of insulation used can impact the wire's ability to dissipate heat. Wires with higher temperature ratings, such as THHN or XHHW, can carry more current than those with lower ratings.

Why Is Copper Preferred Over Aluminum for 100 Amp Wires?

Copper is often the preferred material for 100 amp wires due to its superior conductivity and durability. Copper wires can carry the same amount of current as aluminum wires with a smaller diameter, making them easier to install and less prone to overheating. Additionally, copper is more resistant to corrosion, which extends the lifespan of the wire and reduces the risk of electrical failures.

What Are the Cost Implications of Copper vs. Aluminum?

While copper is more expensive upfront, its long-term benefits often outweigh the initial cost. Copper wires require less maintenance, are less likely to fail, and can be installed in tighter spaces due to their smaller size. Aluminum wires, while cheaper, may require additional measures, such as anti-oxidation compounds and specialized connectors, to ensure safe and reliable performance.

How to Calculate Voltage Drop for 100 Amp Circuits?

Voltage drop is a critical consideration when selecting the wire gauge for 100 amp circuits. It refers to the reduction in voltage as electricity travels through the wire, which can impact the performance of connected devices. To calculate voltage drop, you need to know the length of the wire run, the current being carried, and the resistance of the wire.

The formula for calculating voltage drop is: Voltage Drop = (2 x Length x Current x Resistance) / 1000. For example, if you have a 100-foot run of 2 AWG copper wire carrying 100 amps, the voltage drop would be approximately 3.3 volts. This is well within the acceptable range of 3% for most applications, ensuring efficient operation.

What Are the National Electrical Code Requirements?

The National Electrical Code (NEC) provides guidelines for selecting the appropriate wire gauge for 100 amp circuits. According to the NEC, the wire must be rated for at least 125% of the circuit's amperage to ensure safety. For a 100 amp circuit, this means the wire must be rated for at least 125 amps. Additionally, the NEC specifies the maximum allowable voltage drop for different types of circuits, typically 3% for branch circuits and 5% for feeder circuits.

Conclusion and FAQs

Choosing the right wire gauge for 100 amp circuits is essential for ensuring the safety, efficiency, and performance of your electrical system. By considering factors like wire length, material, ambient temperature, and voltage drop, you can make an informed decision that meets your specific needs. Whether you’re working on a residential or commercial project, understanding these principles will help you avoid costly mistakes and ensure compliance with electrical codes.

Frequently Asked Questions

What is the recommended wire gauge for 100 amp service?

For most 100 amp circuits, a 2 AWG copper wire or a 1/0 AWG aluminum wire is recommended. However, the exact gauge may vary based on the length of the wire run and other factors.

Can I use aluminum wire for 100 amp circuits?

Yes, aluminum wire can be used for 100 amp circuits, but it must be thicker than copper wire to carry the same amount of current. Additionally, special connectors and anti-oxidation compounds may be required.

How do I calculate voltage drop for a 100 amp circuit?

To calculate voltage drop, use the formula: Voltage Drop = (2 x Length x Current x Resistance) / 1000. Ensure the voltage drop is within the acceptable range of 3% for branch circuits and 5% for feeder circuits.

For more information on electrical codes and standards, you can visit the National Fire Protection Association (NFPA) website.

What Wire Size For 100 Amp Service: A Complete Guide

Who Is Michael W. Rogers? A Comprehensive Guide To His Life And Achievements

How Many Calories In Bread: A Comprehensive Guide To Understanding Bread Nutrition

What Is the Correct Wire Size for 100Amp Service? Angi

Speaker wire gauge calculator vetkiza